Welcome to our comprehensive guide to Segment LCDs! Whether you’re an electronics enthusiast, a project designer, or simply curious about the marvels of modern display technologies, you’ve come to the right place.

Let’s demystify Segment LCDs together, explore their advantages, and guide you through choosing, integrating, and troubleshooting these versatile displays in a friendly tone.

Ready to deep dive into the world of Segment LCDs? Let’s get started!

What Is a Segment LCD?

Definition and basic understanding of Segment LCDs

Segment LCDs, or Segment Liquid Crystal Displays, are a type of display technology that allows us to show numbers, characters, and simple icons. Imagine the display on your microwave oven or your old digital watch – clear, straightforward, and incredibly power-efficient. These displays are built from several individual segments that can be turned on or off to form different patterns, mainly numbers and letters.

Advantages of using Segment LCDs in various applications

- Power Efficiency: Segment LCDs are champions when it comes to low power consumption.

- Cost-Effective: They are relatively inexpensive to manufacture, making them a go-to choice for a wide range of products.

- Visibility: With high contrast ratios and a wide viewing angle, they offer exceptional readability, even in direct sunlight.

- Versatility: Their simple design and operation allow them to be easily customized for various applications, from household appliances to medical devices.

How Do Segment LCDs Work?

Segment LCDs operate by manipulating light using liquid crystal cells. When a specific voltage is applied to these cells, they change the polarization of light passing through them, making segments appear as either on or off. Here’s a close look at their technical workings:

The technical workings of Segment LCDs

Electric fields control liquid crystal molecules, dictating how light is directed through the LCD. In essence, by carefully manipulating these fields, a Segment LCD can display the desired pattern on the screen.

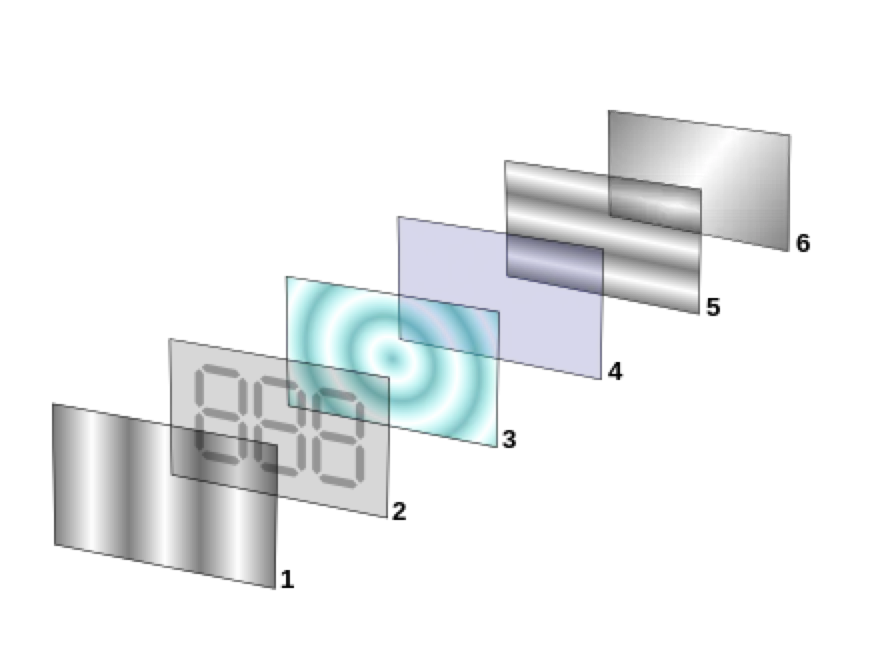

Key components and their functions

- Glass Panels: Hold the liquid crystal material in place and serve as the structural framework.

- Electrodes: Generate electric fields that control the orientation of the liquid crystal molecules.

- Polarizers: These are essential for making the segments visible under various lighting conditions.

6 Key Factors to Consider When Choosing a Segment LCD

When selecting the right Segment LCD for your project, there are several critical factors to consider. Here’s a detailed breakdown of each factor to help you make an informed decision:

1. LCD Technologies

Twisted Nematic (TN)

TN displays are the most common type of LCDs, known for their low cost and fast response times. However, they have limited viewing angles and color reproduction.

High Twisted Nematic (HTN)

HTN displays offer improved contrast and wider viewing angles compared to TN. They are suitable for applications requiring better display performance without a significant cost increase.

Super Twisted Nematic (STN)

STN displays provide even wider viewing angles and better contrast than HTN. They are commonly used in applications where readability from various angles is crucial.

Film Compensated Super Twisted Nematic (FSTN)

FSTN displays are an enhanced version of STN, featuring a film compensator that improves contrast and viewing angles. They are ideal for high-end applications requiring superior display quality.

Vertical Alignment (VA)

VA displays offer the best contrast and viewing angles among the LCD technologies. They are perfect for applications where display quality is a top priority, such as medical devices and high-end instrumentation.

| Technology | Contrast Ratio | Viewing Angles | Response Time | Color Reproduction | Application |

|---|---|---|---|---|---|

| TN (Twisted Nematic) | Low | Limited | Fast | Poor | General-purpose, low-cost applications |

| HTN (High Twisted Nematic) | Medium | Improved | Fast | Fair | Applications requiring better performance than TN |

| STN (Super Twisted Nematic) | High | Wide | Slow | Fair | Applications requiring readability from various angles |

| FSTN (Film Compensated Super Twisted Nematic) | Very High | Very Wide | Slow | Good | High-end applications requiring superior display quality |

| VA (Vertical Alignment) | Highest | Widest | Medium | Excellent | Premium applications where display quality is a top priority |

2. Size and Display Type

Display Size

The size of the display is crucial because it determines how much information you can show and how large the characters and images will be. Consider the physical dimensions of your device and the amount of data you need to display when choosing the size.

Display Type

For segment-based displays like 7-segment, 14-segment, or 16-segment LCDs, focus on the number of segments and their arrangement, as this will dictate the types of characters and symbols you can display.

3. Viewing Angle and Contrast

Viewing Angle

The viewing angle is the angle at which the display can be viewed with acceptable visual performance. A wider viewing angle is essential for applications where the display will be viewed from various angles, ensuring consistent visibility and readability.

Contrast Ratio

The contrast ratio is the difference in luminance between the brightest white and the darkest black that the display can produce. A higher contrast ratio means better readability, especially in bright environments or under direct sunlight. Choose a display with a high contrast ratio for clear and legible text and images.

4. Temperature Range

Operating Temperature

Consider the operating temperature range of the Segment LCD, especially if your device will be used in extreme conditions. Ensure that the display can function properly within the temperature range of your application to avoid damage or degradation of performance.

Storage Temperature

In addition to the operating temperature, consider the storage temperature range of the display. This is important for ensuring the longevity and reliability of the LCD when not in use.

5. Power Consumption

Energy Efficiency

For battery-powered devices, energy efficiency is a priority. Look for Segment LCDs with low power consumption to extend battery life and reduce the need for frequent recharging.

Power Management

Consider displays with power management features, such as automatic sleep or power-down modes, to further conserve energy when the display is not in active use.

6. Customization

Backlighting

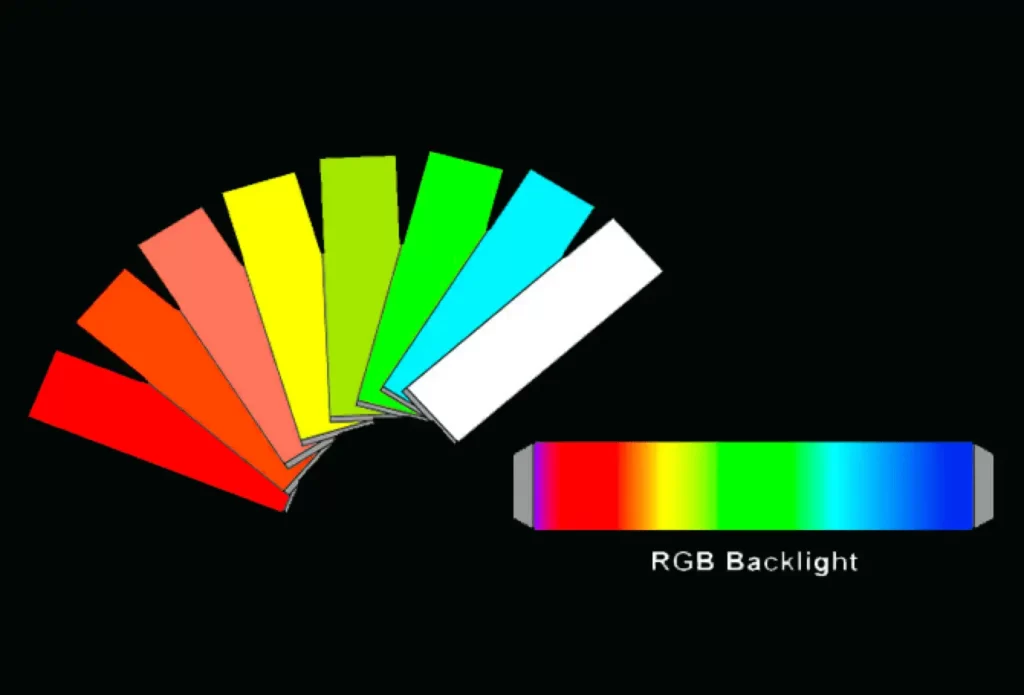

Backlighting is essential for enhancing the contrast and brightness of LCD displays, making them easier to read in various lighting conditions. It’s particularly crucial for applications that operate in dimly lit environments or require consistent visibility throughout the day.

Except for the monochrome backlight, Our RGB backlighting option provides a range of colors, allowing you to tailor the display to your brand’s visual identity or to specific operational requirements. This versatility ensures that your display is not only functional but also aesthetically pleasing.

Check if the manufacturer offers customizable backlighting options to meet your specific needs.

Custom shapes

If you need a display with a unique layout or specific segment shapes, look for manufacturers that provide custom segment options. This allows you to tailor the display to your application’s requirements.

How to Select the Right Segment LCD for Your Application?

To select the right Segment LCD, start by defining your application’s requirements. Consider factors like the environment in which the display will be used, the type of information it needs to show, and how users will interact with it.

Compare different Segment LCD technologies and manufacturers to find the best fit. Don’t hesitate to reach out to suppliers for samples or additional information to ensure the chosen display meets your needs.

How to Integrate Segment LCDs into Your Design?

Preparing for Integration

Gathering Your Tools: Before diving into the integration process, it’s crucial to assemble the right tools and materials. This includes the Segment LCD Display itself, a compatible microcontroller, connecting wires, and possibly a breadboard for prototyping. Also, consider the software aspect, such as development environments and libraries suitable for your microcontroller.

Selecting the right display involves considering size, display type, interface type (e.g., SPI, I2C), and power requirements. Matching these specifications with your project’s needs ensures a seamless integration and optimal performance.

The Integration Process Step-by-Step

Designing the Circuit: The first step is to design a circuit that connects your Segment LCD Display to the electronic design. This involves understanding the pinout of the display and how it interfaces with your microcontroller. Diagrams and datasheets are invaluable resources here, guiding you through the connection process.

Coding for Display Control: Programming is next. Most microcontrollers have libraries or code snippets available to simplify this process. Whether you’re using Arduino, Raspberry Pi, Github or another platform, you’ll find community support and documentation to help control the display, from initializing it to displaying numbers and characters.

Testing the Display: After wiring and programming your display, testing is crucial. Begin with simple patterns or characters to ensure each segment lights up as expected. Troubleshooting common issues might involve checking connections, reviewing code, and ensuring power supply adequacy.

Best Practices for a Smooth Integration

Optimizing Display Readability: To ensure your display is easily readable, consider the ambient lighting conditions it will operate in and adjust the contrast accordingly. Also, managing power consumption is crucial for battery-operated projects; select a display with a suitable power profile and implement power-saving coding techniques.

Reliable connections are vital for the longevity of your project. Using quality materials and ensuring secure soldering can prevent many common issues related to loose connections or wear over time.

How to Connect Segment LCDs to Your System?

Wiring and interfacing Segment LCDs with your system need careful consideration to ensure reliability and performance.

Wiring and connection guidelines

Follow the manufacturer’s guidelines for wiring to avoid common pitfalls like electrical noise and inaccurate display.

Interface options and protocols

Understand the communication protocol required by your chosen display, whether it’s SPI, I2C, or another interface, and prepare your system accordingly.

How to Control Segment LCDs?

Why Is Control Important in Display Applications?

In any display application, control is crucial to ensure that the correct information is displayed accurately and efficiently. For segment LCDs, this means being able to manage each segment to create the desired output.

The Importance of Control: Proper control ensures that the segment LCD displays the correct characters or symbols, maintains readability, and operates efficiently. It’s the key to maximizing the display’s potential and ensuring it meets the application’s requirements.

Methods of Controlling Segment LCDs

There are two primary methods for controlling segment LCDs: the direct drive method and the multiplexed drive method. Each has its advantages and is suitable for different applications.

Direct Drive Method: This method involves controlling each segment directly with a separate electrical connection. It’s simple and provides clear displays but can require many connections for larger displays.

Multiplexed Drive Method: This more complex method reduces the number of connections needed by controlling multiple segments with a single connection. It’s ideal for larger displays but requires careful timing and voltage control.

Choosing the Right Controller for Segment LCDs

Selecting the appropriate controller is crucial for effective segment LCD control. The controller is responsible for managing the voltage applied to the segments and ensuring accurate display.

Factors to Consider: When choosing a controller, consider the display size, power consumption, and required display complexity. Look for controllers that offer the necessary features and compatibility with your segment LCD.

Implementing Control in Segment LCDs

Once you’ve chosen the right controller, implementing control involves setting up the hardware and programming the controller to manage the segment display.

Step-by-Step Guide: Start by connecting the segment LCD to the controller, ensuring all connections are secure. Then, program the controller to control the segments according to your desired display output. Test the setup thoroughly to ensure accurate and reliable performance.

Troubleshooting Common Issues with Segment LCDs

When something goes wrong, it’s essential to approach troubleshooting methodically.

Identifying and resolving common problems

Look out for issues like incomplete segment activation, flickering, or connectivity problems, and systematically test each component.

Maintenance and care tips

Regularly clean your display and check the connections to extend the lifespan of your Segment LCD.

Where to Buy High-Quality Segment LCDs?

Trusted suppliers and manufacturers

Conduct thorough research to find suppliers known for their quality and reliability. Don’t hesitate to ask for samples or technical documentation.

Evaluating quality and reliability

Check reviews, ask for references, and if possible, test the displays under conditions similar to your application.

Final Thoughts

Choosing and implementing a Segment LCD can seem daunting at first, but armed with the right knowledge and resources, you can make an informed decision that elevates your project to the next level.

Remember, the key is to clearly define your requirements, consider the factors mentioned, and not shy away from reaching out to manufacturers for advice.

When it comes to purchasing, go for reputable suppliers who offer the perfect balance between cost and quality, and who provide excellent customer support.

Wait! Before you leave, let us share with you a place where you can get all your LCD display needs under one roof.

Best Place to Buy High-Quality LCD Displays

Are you in search of a reliable LCD display manufacturer for your project needs?

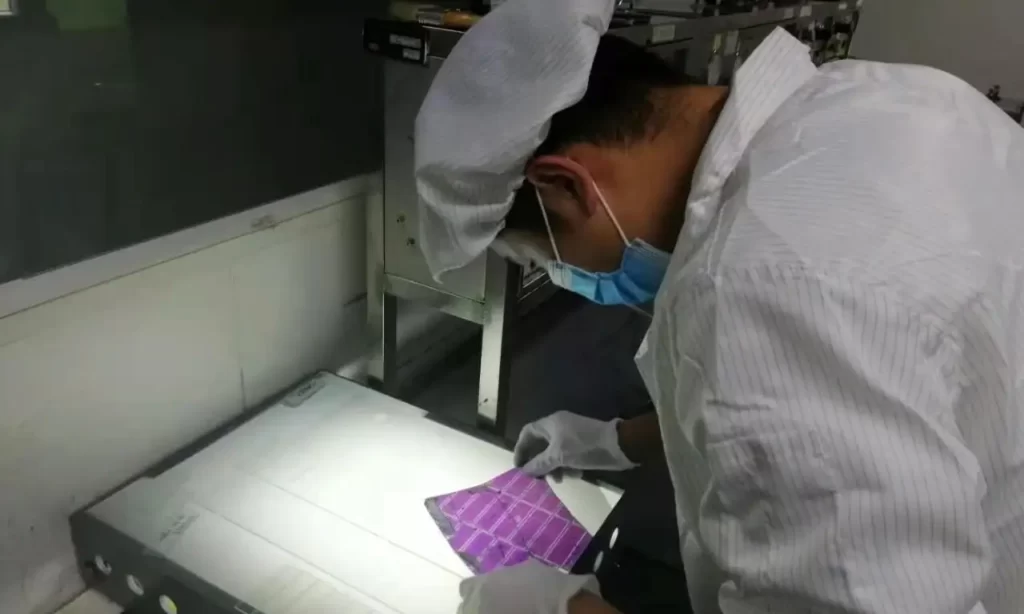

Longtech Optics is a premier Chinese manufacturer of high-quality industrial LCD displays. Our products are crafted in state-of-the-art, dust-free facilities, under the meticulous supervision of experienced technicians and engineers.

Our extensive catalog offers a wide range of top-notch LCD display products, including Character LCDs, Graphic LCDs, Segment LCDs, TFT LCDs, and OLED display modules, all at competitive market prices.

Need something tailored to your specific requirements? We specialize in customization, catering to clients worldwide with our diverse and adaptable product range.

Our LCD displays are not only durable and long-lasting but also adhere to the highest international quality standards.

At Longtech, we pride ourselves on our exceptional 24/7 customer service and offer a FREE project evaluation to get you started. Don’t wait any longer!