Introduction to LCD Technologies

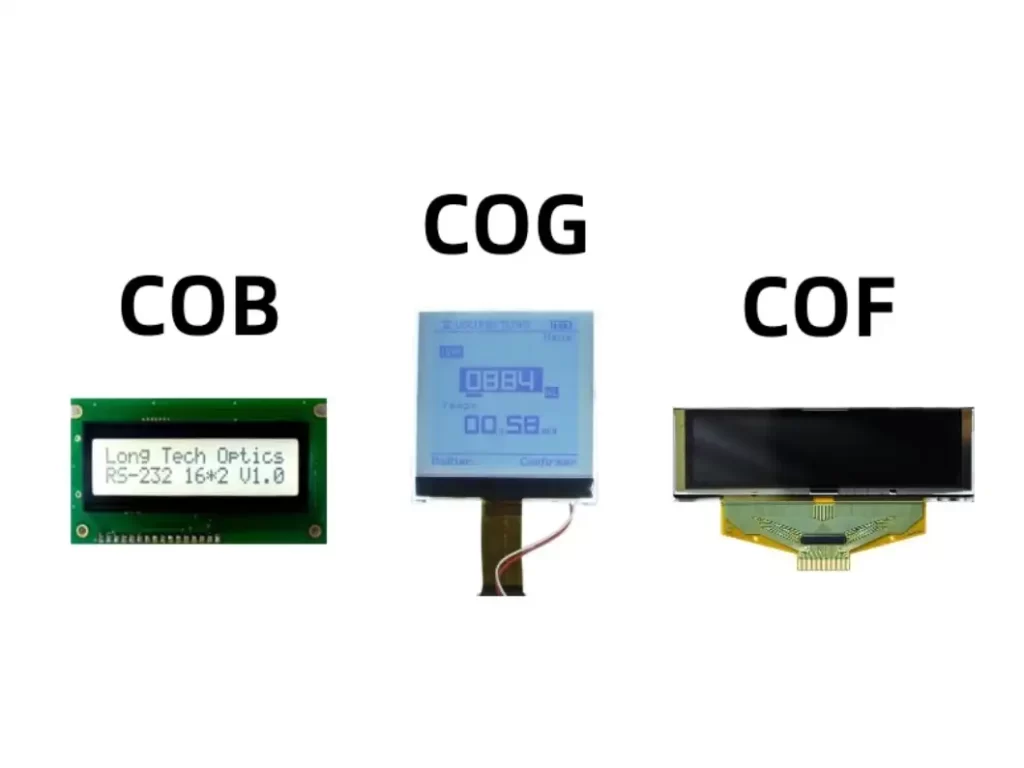

In the realm of electronic displays, the evolution from bulky cathode-ray tubes to sleek, energy-efficient LCD modules represents a significant technological leap. LCD, or Liquid Crystal Display, technology has undergone a series of transformations, leading to the development of distinct types such as COB (Chip On Board), COG (Chip On Glass), and COF (Chip On Film). These advancements not only enhanced display quality but also revolutionized product design across industries.

Understanding the nuances of COB, COG, and COF modules is essential for professionals and enthusiasts alike. Each type offers unique benefits and challenges, making them suitable for various applications. This article dives deep into these three types of LCD modules, comparing their structure, performance, and suitability for different uses.

Differences between COB, COG, and COF

Defining COB, COG, and COF

COB LCD Modules involve the attachment of microchip technology directly onto the printed circuit boards. This integration results in robust, durable modules ideal for high-reliability applications. COG LCD Modules, on the other hand, feature microchips bonded directly to the glass of the display, allowing for thinner, more compact designs. Lastly, COF LCD Modules utilize a flexible film on which the chip is mounted, offering unparalleled flexibility and lightness, suitable for curved or flexible displays.

Comparison of Structural Aspects

Understanding the structural differences between COB, COG, and COF is crucial for determining their appropriateness for various applications. COB’s robustness contrasts with COG’s sleek design and COF’s versatility. Each has unique manufacturing processes, material requirements, and design implications.

Technological Innovations in Each Type

The evolution of COB, COG, and COF modules has been driven by continuous technological innovations. These advancements have improved display quality, energy efficiency, and integration capabilities. Innovations in materials, chip design, and manufacturing processes have played a pivotal role in the development of these modules.

COB LCD Modules: An In-depth Analysis

The Making of COB LCD Modules

COB LCD Modules are created through a process of attaching microchips directly onto the circuit board, then covering them with epoxy or a similar protective substance. This process ensures durability and reliability, especially in harsh environments.

Advantages and Applications

The primary advantage of COB technology lies in its robustness and reliability. These modules are widely used in industrial applications, automotive dashboards, and medical equipment, where durability and longevity are paramount.

Limitations and Considerations

Despite their strengths, COB LCD Modules have limitations, including size constraints and reduced flexibility compared to COG and COF modules. Designers must consider these factors when choosing COB technology for their applications.

Learn more about our Character COB LCDs or Graphic COB LCDs.

COG LCD Modules: Exploring the Technology

The Process Behind COG LCD Production

COG LCD Modules are produced by directly bonding microchips onto the glass substrate of the display. This process allows for a thinner, more compact module design, making COG suitable for modern, sleek electronic devices.

Benefits and Use Cases

The primary benefit of COG technology is its compact size and design flexibility. COG LCD Modules are commonly found in smartphones, tablets, and other consumer electronics where space and aesthetics are crucial.

Challenges and Limitations

While COG offers design advantages, it also presents challenges such as increased complexity in manufacturing and potential fragility. These factors must be considered when implementing COG technology in product design.

Learn more about our COG LCDs.

COF LCD Modules: Emerging Trends

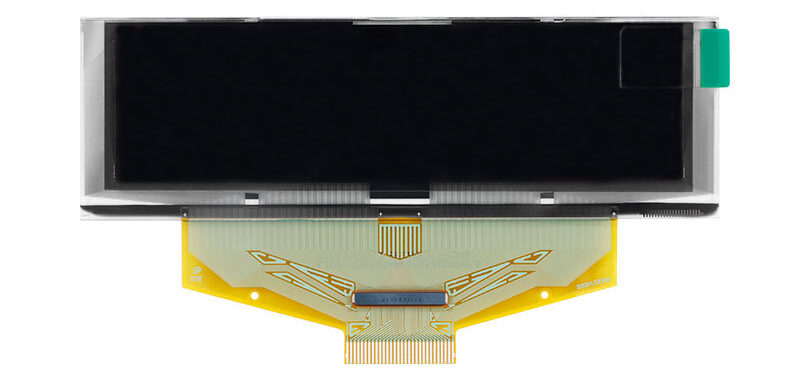

What Sets COF LCD Apart

COF LCD Modules stand out due to their use of a flexible film for chip attachment, enabling them to be used in applications requiring curved or flexible displays. This unique characteristic opens up new design possibilities in the electronics industry.

The Future of COF in Display Technology

The flexibility and adaptability of COF technology position it at the forefront of future display innovations. Its potential applications extend to wearable technology, flexible screens, and other emerging tech areas.

Limitations and Potential Improvements

While COF technology offers exciting possibilities, it also faces challenges like durability concerns and manufacturing complexity. Ongoing research and development aim to address these issues, further enhancing COF’s capabilities.

Comparative Analysis: Performance and Efficiency

Analyzing Performance Metrics

Comparing COB, COG, and COF technologies in terms of performance involves examining parameters like display clarity, response time, and energy consumption. Each technology has its own set of performance metrics that suit different applications.

Efficiency Comparison

Efficiency in LCD modules is measured by energy consumption, heat dissipation, and longevity. COB, COG, and COF each offer different levels of efficiency, influenced by their design and manufacturing processes.

Industry Feedback on Each Module Type

Gathering feedback from industry experts and users provides insights into the real-world performance and efficiency of COB, COG, and COF modules. Such feedback is invaluable for understanding the practical implications of each technology.

Industry Applications: COB, COG, and COF

Key Industries Using COB

COB technology finds its place in industries requiring robust and durable displays, such as automotive, industrial control systems, and medical equipment. Its reliability under harsh conditions makes it a preferred choice in these sectors.

COG’s Role in Modern Devices

COG technology is prevalent in consumer electronics, where compact design and sleek aesthetics are key. Smartphones, tablets, and ultraportable laptops often employ COG LCD Modules for their thin profiles and high-quality displays.

Emerging Markets for COF

COF technology is rapidly gaining traction in innovative markets like wearable tech, flexible electronics, and futuristic automotive displays. Its unique flexibility and adaptability make it ideal for cutting-edge applications.

Design Considerations in Choosing LCD Modules

Factors Influencing Module Choice

Selecting the appropriate LCD module type involves considering factors such as application environment, design requirements, and cost constraints. Each module type offers different advantages that must be weighed against these factors.

Customization and Flexibility in Design

The ability to customize and adapt LCD modules to specific product designs is a critical consideration. COB, COG, and COF each offer varying degrees of customization and design flexibility, impacting their suitability for different projects.

Cost-Benefit Analysis of Each Type

Evaluating the cost-effectiveness of COB, COG, and COF modules involves not just their initial cost but also their longevity, maintenance requirements, and overall value proposition in the long term.

Learn more about Selecting the Best LCD Display For Your Application

Future Trends and Developments

Innovations on the Horizon

The LCD module industry is continuously evolving, with research and development focusing on improving display quality, energy efficiency, and integration capabilities. Upcoming innovations in materials and manufacturing processes are expected to drive further advancements.

Market Predictions and Trends

Market trends indicate a growing demand for more efficient, flexible, and high-quality display technologies. COB, COG, and COF modules are likely to see enhanced applications and improvements in response to these market demands.

The Role of Consumer Demand in Shaping Developments

Consumer preferences play a significant role in shaping the future of LCD technologies. The demand for sleeker, more versatile, and energy-efficient displays drives the ongoing evolution of COB, COG, and COF modules.

Environmental Impact and Sustainability

Eco-Friendly Practices in LCD Module Production

Sustainability is becoming increasingly important in the electronics industry. Eco-friendly practices in the production of COB, COG, and COF modules, such as reducing waste and using recyclable materials, are gaining prominence.

Sustainability in the Lifecycle of LCD Modules

The environmental impact of LCD modules extends beyond their production to their use and disposal. Efforts are being made to enhance the sustainability of these modules throughout their lifecycle, including energy-efficient designs and recyclability.

Future Directions for Green Technologies

The future of LCD module technology is closely tied to environmental considerations. Advances in green technologies and sustainable practices are expected to play a significant role in the next generation of COB, COG, and COF modules.

User Experience and Interface Design

Enhancing User Experience with Different LCD Modules

The choice of COB, COG, or COF technology can significantly impact user experience. Factors like display clarity, response time, and aesthetic design contribute to the overall user satisfaction and usability of electronic devices.

Interface Design Considerations

Effective interface design in electronic devices relies on the capabilities and limitations of the chosen LCD module. Designers must consider aspects such as resolution, color accuracy, and viewing angles when selecting COB, COG, or COF modules.

Case Studies: Successful Implementations

Examining case studies of successful implementations of COB, COG, and COF technologies provides valuable insights into their practical applications and benefits. These real-world examples illustrate how each technology can be optimally utilized in different product designs.

Technical Challenges and Solutions

Overcoming Common Technical Hurdles

Technical challenges in the use of COB, COG, and COF modules, such as integration difficulties, durability concerns, and manufacturing complexities, require innovative solutions. Sharing knowledge and expertise in this area can aid in overcoming these challenges.

Innovative Solutions in LCD Module Technology

The continuous advancement of LCD module technology involves developing novel solutions to existing technical problems. Innovations in materials, design, and manufacturing processes are key to addressing these issues.

Expert Opinions and Advice

Seeking the opinions and advice of industry experts is invaluable for staying abreast of the latest developments and best practices in LCD module technology. These insights can guide designers and manufacturers in making informed decisions.

Conclusion: The Future of LCD Module Technology

In conclusion, the comparison of COB, COG, and COF LCD modules reveals a dynamic and evolving landscape in display technology. Each type offers distinct advantages and challenges, making them suitable for a range of applications. The future of LCD modules is bright, with ongoing innovations expected to further enhance their performance, efficiency, and environmental sustainability. As we look ahead, it’s clear that COB, COG, and COF technologies will continue to play a significant role in shaping the future of electronic displays.