A Complete Industrial Navigation for Engineers and Procurement Teams

By Zhong — LCD Display Expert at Longtech Optics Co., Ltd.

1. Introduction — Why This Guide Exists

In 2025, many teams still come to me asking the same question:

“How do I correctly design a custom segment LCD from scratch?”

They know segment LCDs are stable.

TFT and OLED face frequent supply risks.

industrial products need 5–10 years of continuous production.

But they don’t know the correct engineering sequence.

which parameters matter most.

why some icons look blurry after production.

why one polarizer works and another doesn’t.

what causes a cost jump of 40–60%.

This guide solves all of that.

I wrote it because most custom LCD projects fail not due to technology but due to misunderstanding.

optical modes.

segment design rules.

IC limitations.

manufacturing constraints.

My goal is simple:

When an engineer reads this guide, they can design an LCD correctly the first time.

When a procurement manager reads this guide, they can understand cost drivers and make smarter decisions.

This is the most complete and updated segment LCD design navigation for 2025.

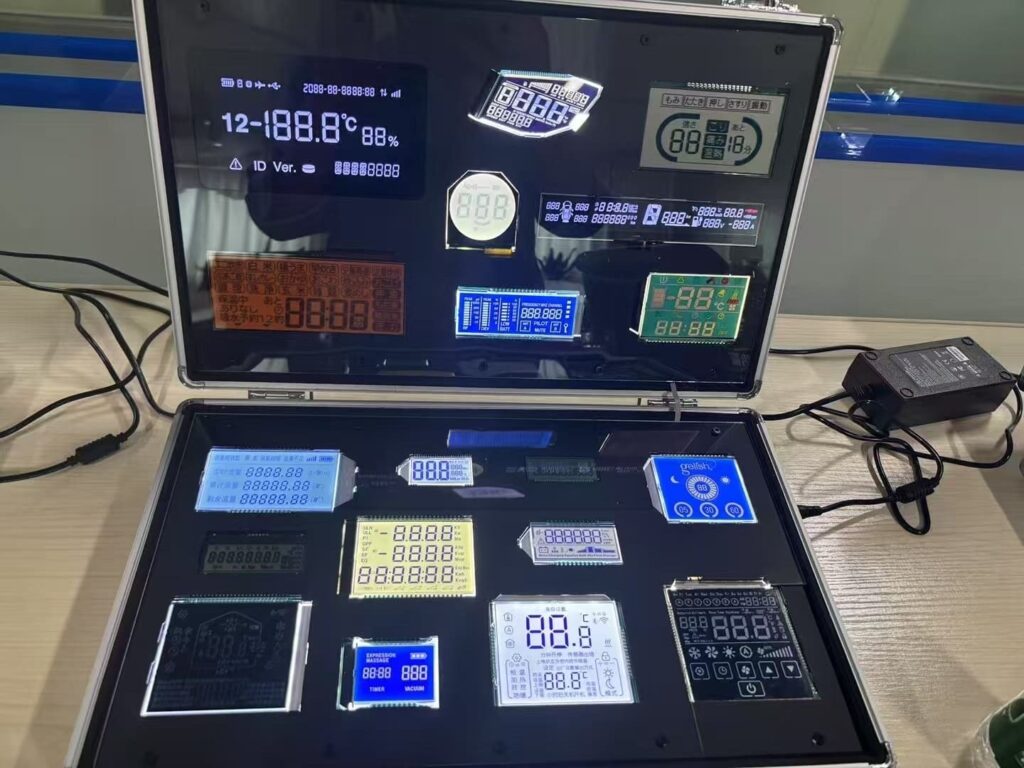

2. 2025 Navigation for Custom Segment LCD — The Roadmap

Why this section matters:

Most LCD projects fail because teams choose the wrong sequence.

People jump into drawings too early.

People think backlight comes before environment.

People select IC before confirming duty/bias.

These lead to redesign, extra cost, and waste.

That’s why I always start with a fixed 9-step roadmap.

2025 LCD Customization Roadmap

- Define the viewing environment

- Select LCD technology (TN / STN / FSTN / VA)

- Design segments and icons with strict DFM rules

- Choose the polarizer and optical stack

- Plan backlight options (if needed)

- Select driver IC and interface

- Choose mechanical structure (COG / COB / PIN / Zebra)

- Define reliability requirements

- Plan production flow and schedule

Every successful LCD project follows this path.

Every failed LCD project breaks it.

In the next sections, I will explain why each step exists and what industrial customers must consider.

3. Define the Working Environment — Because Environment Controls Everything

Why this section matters:

If the environment is wrong, everything is wrong.

No IC, no backlight, no polarizer can fix a display designed for the wrong environment.

Environment is the foundation that every decision depends on.

I always start with this question:

“Where will the display be used, and under what lighting conditions?”

3.1 Indoor Applications

Indoor conditions are stable.

Light level is predictable.

Reflection is manageable.

For indoor products, I normally recommend:

- STN or FSTN

- Transmissive or Transflective polarizers

- Backlight required

- Standard 3H hard coating

Typical indoor products:

- Blood pressure monitors

- Thermometers

- Medical analyzers

- Coffee machines

- Home appliances

- Industrial instruments

Indoor screens rely on consistent contrast.

FSTN delivers the best performance for this.

3.2 Outdoor Applications

Outdoor environments change constantly.

Sunlight, shadows, reflections, temperature shifts — all matter.

For outdoor use, I recommend:

- VA LCD or Reflective FSTN

- Reflective or Transflective polarizer

- Anti-glare surface

- Wide temperature range (-30°C to 85°C)

- No reliance on backlight

Typical outdoor products:

- Smart meters

- Gas/water/electric meters

- Solar devices

- EV chargers

- Outdoor controllers

- Industrial sensors

Wrong choice here → display unreadable under sun.

This is the most common mistake I see.

3.3 Viewing Angle Orientation

Segment LCDs have directional viewing due to liquid crystal alignment.

General rules:

- Devices used lower than eye level → 6 o’clock

- Devices mounted above eye level → 12 o’clock

- Horizontal position → customized tilt recommended

- Automotive indicators → VA for wide angle

Choose incorrectly → digits appear washed out or inverted.

3.4 Why environment is step 1

Because it directly determines:

- LCD technology

- Polarizer

- Backlight

- Contrast performance

- Icon design

- Supply voltage

- Mechanical thickness

This is why I always warn customers:

If you choose the wrong environment, every downstream decision becomes a mistake.

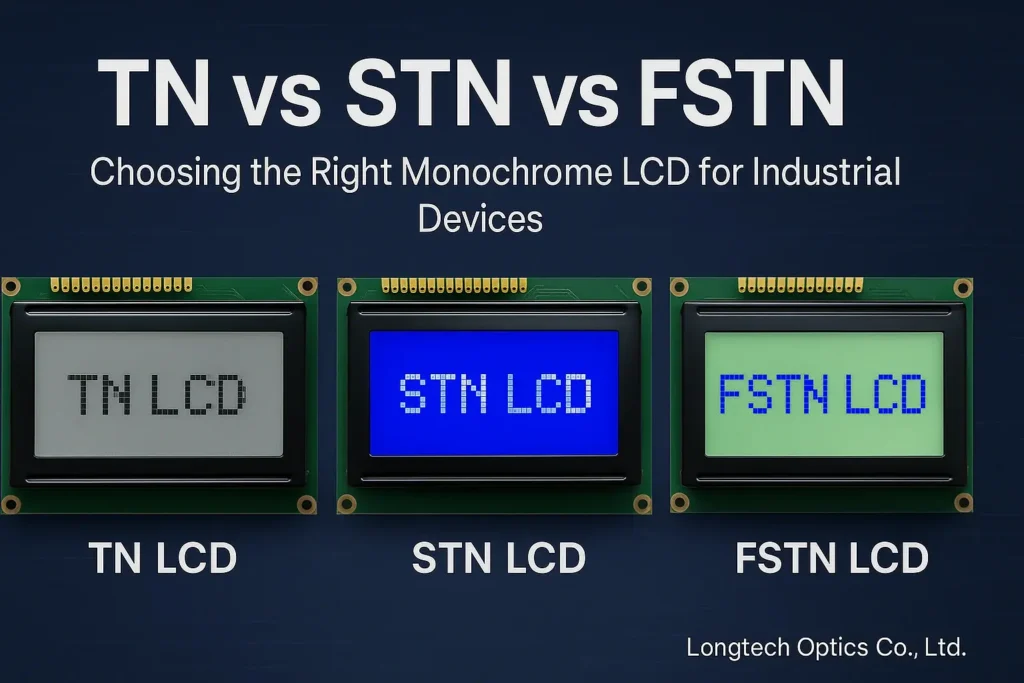

4. Choose LCD Technology — Because Optical Behavior Defines Usability

Why this section matters:

TN, STN, FSTN, and VA are not “better or worse” —

they are optimized for different scenarios.

Choosing the wrong technology leads to:

- low contrast

- narrow viewing angle

- poor outdoor readability

- high failure rate in cold or hot environments

Here is the simplest and most practical comparison.

4.1 TN (Twisted Nematic)

- Lowest cost

- Fast response

- Limited viewing angle

- Basic contrast

- Best for simple numeric-only displays

Not suitable for modern industrial devices requiring strong readability.

4.2 STN (Super Twisted Nematic)

- Better contrast than TN

- Larger viewing angle

- Low cost

- Good for standard industrial instruments

Most cost-effective for simple industrial products.

4.3 FSTN (Film compensated STN)

- High contrast

- Darker background

- More uniform appearance

- Better readability

- Excellent for indoor medical devices

I use FSTN in 70% of indoor segment LCD projects.

4.4 VA LCD (Vertical Alignment)

- Highest contrast

- Best sunlight readability

- Deep black digits

- Very wide viewing angle

- Premium appearance

If your customer sees VA once, they will never want STN again.

4.5 How technology affects overall cost and design

LCD technology impacts:

- polarizer type

- backlight brightness

- segment readability

- power consumption

- driver IC selection

This is why choosing the right technology early saves time and money.

Learn more about TN vs STN vs FSTN: How to Choose the Right Monochrome LCD for Industrial Devices

5. Segment Layout & Icon DFM Rules — Because 80% of Problems Come From the Drawing

Why this section matters:

Segment LCD quality is determined by the drawing.

Not the IC.

Not the backlight.

Not the polarizer.

The drawing.

If the drawing is wrong, no manufacturing process can fix it.

5.1 Minimum Stroke Width

I always follow this rule:

- Recommended: ≥ 0.18 mm

- Minimum: 0.15 mm

Thin strokes cause:

- poor contrast

- incomplete darkening

- segment breakage

- low lifetime

5.2 Segment Gap

- Recommended: ≥ 0.20 mm

Why this matters:

- Too small → segments bleed together

- Too large → digits look weak or skinny

Segment gaps define digit aesthetics.

5.3 Icon Complexity

LCD is not OLED.

It cannot display ultra-detailed shapes.

Avoid:

- thin curved lines

- tiny icons

- overly complex symbols

- intricate logos

Keep shapes clean and simple.

Industrial customers care about clarity, not ornamental graphics.

5.4 Viewing Distance

The typical reading distances:

- Medical devices: 20–30 cm

- Home appliances: 30–50 cm

- Industrial dashboards: 70–100 cm

Selecting stroke width and segment size requires knowing reading distance.

5.5 DFM Mistakes I See Every Month

- Digit 8 becomes “blurred circle” due to excessive complexity

- Icon lines too thin → disappear under certain angles

- Tight segment spacing → low yield in production

- Designers use PC font → LCD cannot replicate it

This is why I always ask for early DFM review.

6. Polarizer Selection — Because Polarizer Controls 60% of Display Quality

Why this section matters:

Most engineers ignore polarizers.

But polarizers determine contrast, reflectivity, glare, and sunlight readability.

Choosing wrong polarizer → display becomes unusable.

6.1 Reflective Polarizer

- Uses ambient light

- Excellent for sunlight

- Zero power consumption for readability

- Ideal for meters

6.2 Transflective Polarizer

- Balanced solution

- Indoor + outdoor

- Works with backlight

- Best for mixed environments

6.3 Transmissive Polarizer

- Backlight-required

- Indoor only

- High brightness

- Not for sunlight

6.4 Surface Treatments

- 3H Hard coating → anti-scratch

- AG (Anti-glare) → haze 8–12%

- AR (Anti-reflective) → premium instruments

- AF (Anti-fingerprint) → medical use

Surface treatment significantly impacts reading comfort.

Learn more about Transmissive vs Reflective vs Transflective Displays

7. Backlight Planning — Because It Affects Power, Thickness, and Aesthetics

Why this section matters:

Backlight is not just illumination.

It affects:

- overall thickness

- brightness uniformity

- power consumption

- cost

- optical quality

7.1 When backlight is needed

- Indoor devices

- Night operations

- Medical equipment

- Home appliances

7.2 Backlight Color

- White → universal

- Green → high contrast

- Blue → modern and stylish

- Amber → warm tone

- Red → alerts

7.3 Backlight Position

Side-light

- thin

- efficient

- modern

Bottom-light

- more uniform

- easier to manufacture

7.4 Backlight Lifetime

Industrial requirement:

≥ 50,000 hours

A cheap backlight will reduce reliability.

Learn more about What is LED Backlight?

8. Driver IC & Interface — Because IC Controls Vop, Contrast, and Lifetime

Why this section matters:

If you choose the wrong IC, the entire design collapses.

8.1 Duty and Bias Settings

These directly affect:

- power consumption

- contrast

- lifetime

- stability

Typical multiplexing:

- 1/3 duty

- 1/4 duty

- 1/6 duty

- 1/8 duty

Higher multiplex → fewer pins → lower segment clarity.

8.2 Interface Options

- Direct drive GPIO

- SPI

- I2C

- Parallel

Choose based on MCU and system complexity.

8.3 IC Availability in 2025

Many old LCD ICs are now EOL.

At Longtech, we only choose ICs with 5–10 year guaranteed supply.

9. Mechanical Structure — Because Thickness and Reliability Depend on Structure

Why this section matters:

The mechanical structure defines:

- thickness

- assembly method

- vibration resistance

- cost

- appearance

9.1 COG (Chip on Glass)

- Thinnest

- Strong against vibration

- Premium finish

- Used in medical devices

9.2 COB (Chip on Board)

- Most cost-efficient

- Easy to assemble

- Great for appliances or tools

9.3 PIN Module

- Plug-and-play

- Strong connectors

- Used in DIY, consumer appliances

9.4 Zebra Connector

- Low profile

- Flexible

- Good for compact devices

10. Reliability & Temperature — Because Industrial Devices Must Survive Years of Use

Why this section matters:

Industrial devices must last.

LCDs must tolerate harsh environments.

10.1 Temperature Performance

- Operating: -20~70°C

- Wide temp: -30~85°C

- Storage: -40~90°C

10.2 Humidity Testing

- 60°C / 90% RH

10.3 UV Resistance

Critical for outdoor meters.

10.4 Vibration & Shock

Industrial certificates require:

- 5–500 Hz

- Drop tests

11. Production Workflow — Because Time-to-Market Must Be Controlled

Why this section matters:

Knowing the correct process prevents delays and miscommunication.

11.1 Step-by-step flow

- Submit drawing

- DFM review

- Optical & IC confirmation

- 2D mechanical drawing

- Sample production (2–3 weeks)

- Mass production (4–5 weeks)

Clear, predictable, and industrial-grade.

12. Cost Structure — Because You Should Lower Cost Scientifically

Why this section matters:

Cost shouldn’t be lowered blindly.

Wrong cost-cutting damages readability or lifetime.

12.1 What affects cost

- Glass size

- Segment count

- ITO complexity

- Polarizer type

- Backlight

- IC selection

- Structure (COG/COB)

12.2 Typical price ranges

- Simple → $0.25–$0.40

- Medium → $0.40–$0.90

- Large → $1.20–$2.80

Industrial cost is driven by stability, not ultra-low prices.

13. Engineering Checklist — Because Engineers Need a Final Validation Tool

An effective engineering checklist prevents mistakes.

I provide this checklist to all B2B clients to ensure that all key items are reviewed before production.

14. Why Choose Longtech — Because We Are a Monochrome Specialist

We focus on:

- industrial-grade TN/STN/FSTN/VA

- segment LCDs

- COG/COB solutions

- 3–10 year supply guarantee

- thousands of no-mold-fee standard models

We are not a TFT/OLED company.

We are specialists in monochrome displays.

This is why companies trust us for long-term projects.

15. Conclusion — Because Good LCD Design Saves Time, Money, and Risk

A well-designed segment LCD:

- lasts over a decade

- consumes minimal power

- remains readable in all conditions

- is cost-effective

- is reliable for industrial use

If you have a drawing or concept, send it to me.

I will check it with the full 2025 rules above and guide you through the entire engineering flow.

Let’s build an LCD that will survive for years — stable, readable, and precise.