In the dynamic field of display technology, the debate between glass and plastic as the core material for LCD screens is a pivotal one. As an expert specializing in LCD displays at Longtech Optics Co. Ltd, with over two decades of experience, I’ve seen the transformative role these materials play in shaping the evolution and functionality of LCDs. The choice between glass and plastic is not just a matter of preference but a strategic decision that impacts everything from manufacturing processes to the end-user experience.

At the heart of this discussion lies the fundamental question: is an LCD made of glass or plastic? The answer is both. LCDs, or Liquid Crystal Displays, use a combination of glass and plastic in their construction, with each material contributing unique properties essential for optimal performance. Glass is known for its clarity and durability, while plastic offers unmatched flexibility and lightweight characteristics. Understanding the interplay between these materials is key to appreciating the intricacies of LCD technology.

This deep dive into the composition of LCDs will unravel the complexities and nuances of each material. By comprehending their roles, we can better understand the technological marvels that are LCD screens and appreciate the advancements that have been made in this field.

Understanding LCD Technology

The Essence of LCDs

Liquid Crystal Displays, commonly known as LCDs, represent a significant segment of the display market. These displays are integral to numerous devices, ranging from large-scale televisions to intricate instrument panels. At their core, LCDs consist of a liquid crystal solution that modulates light to render images. This liquid crystal layer is sandwiched between substrates, which historically have been glass but increasingly include plastic alternatives.

Operational Principles of LCDs

LCDs function by manipulating light. Unlike emissive displays that generate light, LCDs control the passage of external light through the liquid crystals. These crystals, aligned in precise patterns, twist or untwist in response to electric currents, altering the light’s path. This modulated light then travels through various layers, including color filters and polarizers, to produce the final image we see.

LCD Material Composition

The Predominance of Glass in LCDs

Glass: The Traditional Choice

Historically, glass has been the material of choice for LCDs. Its inherent properties like transparency, rigidity, and chemical stability make it an ideal substrate. The glass used in LCDs is not ordinary glass but a specialized type, often chemically strengthened to enhance durability and resist scratches.

Varieties of Glass in LCDs

- Borosilicate Glass: Known for its low thermal expansion and high chemical resistance.

- Aluminosilicate Glass: Favoured for its scratch resistance and toughness.

These glass types undergo specific treatments to optimize them for display purposes, enhancing their clarity, durability, and suitability for various environmental conditions.

Role of Glass in LCD

- Structural Stability: Glass provides a stable and rigid structure, essential for the precise alignment of liquid crystals.

- Optical Excellence: The high transparency and low distortion of glass contribute to superior image quality.

- Thermal and Chemical Resistance: Glass maintains its properties across a wide range of temperatures and environments, making it reliable for diverse applications.

The Rise of Plastic in LCDs

The Advent of Plastic Displays

The integration of plastic in LCD technology marks a significant evolution in the field. Plastic substrates, often made from materials like Polycarbonate (PC) or Polyethylene Terephthalate (PET), bring new dimensions of flexibility and weight reduction to displays.

Benefits of Plastic in LCDs

- Flexibility: Plastic’s malleability allows for the creation of bendable and foldable displays, opening new avenues in design and application.

- Lightweight Nature: The reduced weight of plastic is a game-changer for portable and wearable devices.

- Innovative Applications: Plastic enables unconventional display formats, including curved and rollable screens.

Challenges with Plastic

While plastic offers distinct advantages, it also presents challenges:

- Durability: Plastic is generally more prone to scratches and wear compared to glass.

- Optical Quality: Achieving the same level of clarity and minimal distortion as glass is a complex task for plastic substrates.

Glass vs. Plastic: A Comparative Analysis

Durability and Longevity

Glass, with its scratch resistance and rigidity, generally offers greater longevity. In contrast, plastic, though less prone to shattering, can suffer from wear and tear more quickly.

Clarity and Image Quality

Glass leads in providing crisp, clear images with minimal distortion. Plastic, despite advancements, still trails in this aspect, though it’s rapidly improving.

Manufacturing and Cost Implications

Glass manufacturing, especially the specialized types used in LCDs, is a complex and costly process. Plastic, being easier to mold and produce, offers cost advantages and greater design flexibility.

Environmental Considerations

Both materials pose environmental challenges. Glass manufacturing is energy-intensive, while plastic raises concerns regarding recyclability and ecological impact.

The Future Trajectory

The future of LCD technology will likely see a blend of both materials, with each being chosen based on the specific requirements of the application. Innovations in plastic technology are narrowing the gap with glass, especially in terms of optical quality and durability.

Advantages and Disadvantages of Each Material

Pros and Cons of Using Glass in LCDs

Advantages of Glass

- Optical Superiority:

- Unmatched Clarity: The type of glass used in LCD displays, often chemically strengthened, offers unparalleled transparency. This high level of clarity is essential for producing sharp, vivid images, which is especially crucial in high-definition displays.

- Consistent Color Reproduction: Glass provides consistent and accurate color reproduction. This feature is critical in applications where color precision is paramount, such as in professional photography monitors or medical imaging devices.

- Reduced Optical Distortion: High-quality glass ensures minimal optical distortion. This aspect is vital in applications where image accuracy is critical, such as in aviation displays or precision engineering monitors.

- Durability and Longevity:

- Scratch Resistance: Glass surfaces, especially those that are chemically treated, are highly resistant to scratches. This durability is essential for maintaining the display’s aesthetic and functional integrity over time.

- Sustained Performance: The rigidity and stability of glass contribute to the longevity of the LCD display. It helps maintain the alignment of the liquid crystals, which is crucial for consistent display performance over the years.

- Resistance to Environmental Stress: Glass is highly resistant to various environmental factors, including extreme temperatures, humidity, and UV exposure. This resistance makes it an ideal choice for outdoor displays or devices used in harsh industrial environments.

- Stability and Reliability:

- Thermal Consistency: Glass maintains its properties across a wide temperature range, ensuring stable display performance even under varying environmental conditions.

- Chemical Inertness: Glass is chemically inert, meaning it doesn’t react with other materials or chemicals it might come into contact with. This property ensures the longevity and reliability of the LCD display.

- Non-Porous Surface: The non-porous nature of glass prevents the absorption of moisture and contaminants, which could otherwise affect the display’s functionality.

Disadvantages of Glass

- Fragility and Breakage Risk:

- Prone to Cracking: Despite its durability, glass is susceptible to cracking or shattering upon impact. This fragility can be a significant drawback in portable devices or in situations where the display might be subject to physical stress.

- Safety Concerns: In scenarios where glass breaks, it can pose safety risks, particularly in public spaces or in consumer electronics used by children.

- Weight and Handling:

- Heavier than Plastic: Glass panels are inherently heavier than plastic, which can be a limiting factor in the design of portable and handheld devices.

- Handling and Installation: The additional weight and fragility of glass require careful handling during the manufacturing process and installation, which can increase labor and transportation costs.

- Manufacturing Complexity and Cost:

- Complex Production Processes: The production of high-quality glass for LCDs involves complex processes, including chemical strengthening and precision cutting, which are both time-consuming and costly.

- Higher Material Costs: The materials and processes involved in manufacturing glass for LCD displays typically result in a higher cost compared to plastic, which can affect the final price of the product.

Pros and Cons of Using Plastic in LCDs

Advantages of Plastic

- Flexibility:

- Design Innovation: Plastic’s inherent flexibility opens up a world of design possibilities. This flexibility allows manufacturers to create curved, bendable, or even foldable screens, which can revolutionize the way we interact with our devices.

- Adaptability: The malleability of plastic makes it adaptable to a variety of uses, from wearable technology to unconventional display shapes in consumer electronics.

- Lightweight:

- Portability: Plastic’s lightweight nature is a significant advantage for portable devices. It makes devices easier to handle and carry, which is particularly beneficial for mobile phones, tablets, and wearable technology.

- User Comfort: In devices like VR headsets or wearable tech, the reduced weight due to plastic usage enhances user comfort, allowing for longer periods of use without discomfort.

- Cost-Effective:

- Lower Manufacturing Costs: Plastic substrates are generally cheaper to produce than glass. This cost-effectiveness arises from the less complex manufacturing processes and the lower material costs.

- Economies of Scale: The ease of producing plastic at scale further drives down costs, making devices more affordable for a broader range of consumers.

Disadvantages of Plastic

- Optical Quality:

- Clarity and Sharpness: While advancements have been made, plastic still generally falls short of the optical clarity and sharpness that glass provides. This difference can be noticeable in high-resolution displays where every detail counts.

- Color Fidelity: Plastic may not always render colors as accurately as glass, which can be a drawback for applications requiring precise color reproduction.

- Durability:

- Scratch Susceptibility: Plastic is more prone to scratches compared to glass. This susceptibility can lead to a deterioration in visual quality over time, especially in high-use environments.

- Wear and Tear: Plastic displays may not have the same longevity as glass, requiring more frequent replacements or repairs, which can offset the initial cost savings.

- Environmental Concerns:

- Recyclability: Although plastic is lightweight and flexible, its recyclability is a concern. Not all plastics used in LCDs are easily recyclable, posing environmental challenges.

- Ecological Impact: The production and disposal of plastic materials can have significant ecological impacts, raising concerns about sustainability and environmental stewardship.

Impact on Display Quality and Durability

The choice between glass and plastic significantly influences the display quality and durability of LCDs. Glass, with its superior optical properties and durability, ensures high-quality, long-lasting displays. On the other hand, plastic offers flexibility and cost benefits, although at the expense of some degree of optical quality and durability. The decision ultimately depends on the specific requirements and constraints of the application.

Industry Trends and Innovations

Recent Advancements in LCD Technology

The LCD industry has witnessed significant advancements in recent years. Innovations include improved manufacturing techniques for both glass and plastic substrates, leading to better quality and more diverse applications. Developments in liquid crystal technology and backlighting systems have also contributed to more energy-efficient and visually appealing displays.

Future Trends: Moving Towards Glass or Plastic?

The future of LCD technology seems to be embracing a hybrid approach, where both glass and plastic find their unique applications. The trend is moving towards thinner, lighter, and more flexible displays, which suggests an increasing role for plastic. However, glass remains irreplaceable for applications where optical quality and durability are paramount.

Conclusion

In summary, both glass and plastic play critical roles in the construction and performance of LCDs. Glass stands out for its optical quality and durability, while plastic offers flexibility and cost advantages. The choice between these materials depends on a balance of factors like display quality, durability, design requirements, and cost considerations. As technology advances, we can expect to see continued innovations in both materials, further enhancing the capabilities and applications of LCDs.

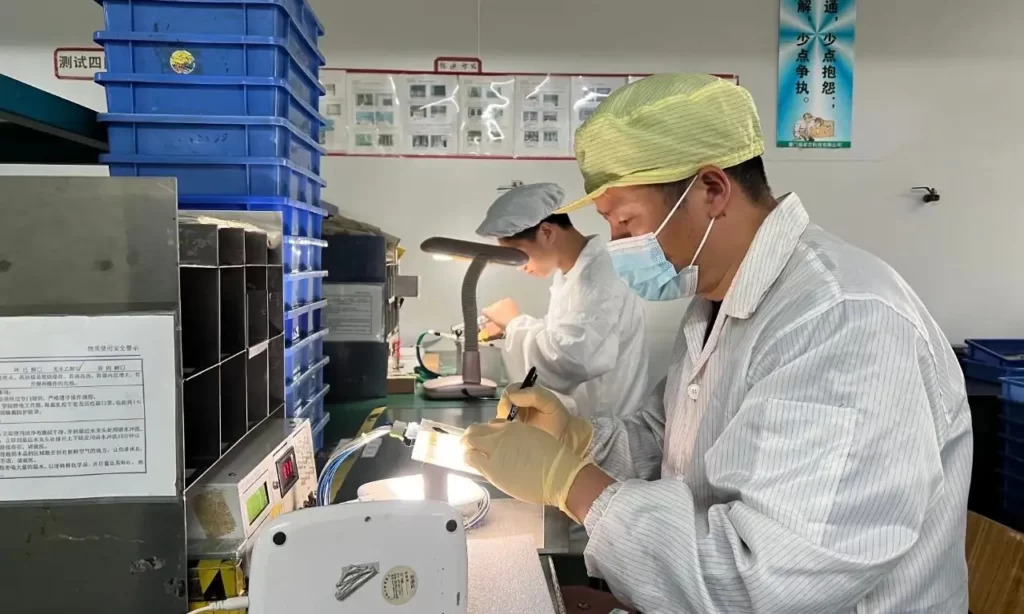

Why Choose Us?

For those intrigued by the intricacies of LCD technology and looking to explore state-of-the-art display solutions, I invite you to discover more about Longtech Optics Co. Ltd’s offerings. Our extensive experience and commitment to innovation position us uniquely to provide high-quality LCD solutions tailored to your specific needs. Let’s get started with us!