OLED Display Module

OLED Display Manufacturer

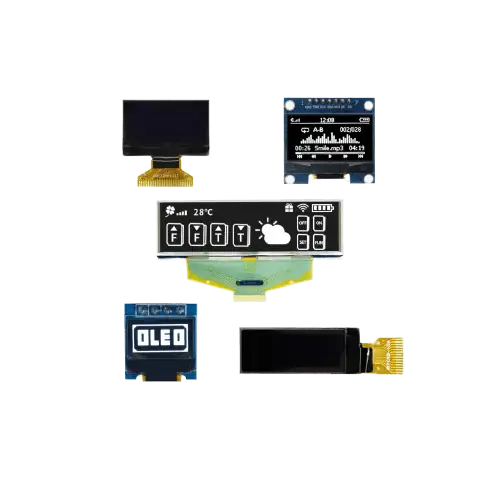

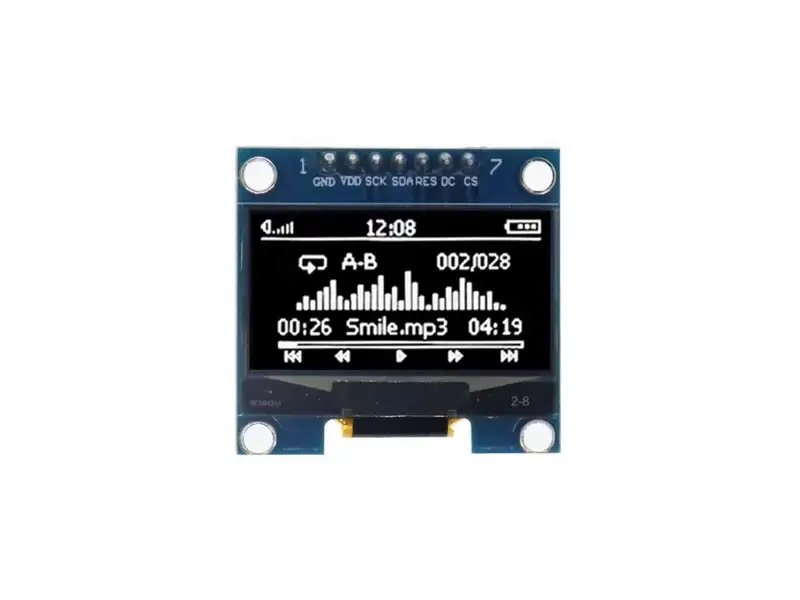

Longtech offers a wide range of OLED display modules in sizes from 0.31″ to 5.5” OLED and a wide range of standard graphic Monochrome OLED modules. Our graphic monochrome OLEDs are available in dot matrix format of graphic resolution including 64×32, 128×32, 128×64, 256×64 and etc.

Using our nearly 20 years of expertise and advanced display technologies, we can modify our existing products or develop a completely unique solution for your application. Our dedicated team will be with you at every step, ensuring a successful result.

Standard Specifications

| Item | Inch | Dot matrix | Display color | Module size(mm) | Viewing area(mm) | Interface | Driver IC |

| LGO3262A-031 | 0.31″ | 32 x 62 | White | 6.2 x 11.88 x 1.0 | 3.82 x 6.986 | I2C | ST7312 |

| LGO6032A-032 | 0.32″ | 60 x 32 | White | 9.96 x 8.85 x 1.2 | 7.06 x 3.82 | I2C | SSD1315 |

| LGO7240A-042 | 0.42″ | 72 x 40 | White | 12.0 x 11.0 x 1.25 | 9.196 x 5.18 | I2C, SPI | SSD1315 |

| LGO6432A-049 | 0.49″ | 64 x 32 | White | 15.0 x 16.0 | 12.58 x 6.98 | I2C | SSD1306 |

| LGO4888A-050 | 0.50″ | 48 x 88 | White | 8.928 x 17.1 x 1.227 | 6.124 x 11.244 | I2C | CH1115 |

| LGO9632A-054 | 0.54″ | 96 x 32 | White | 18.52 x 7.04 x 1.227 | 12.46 x 4.14 | I2C | CH1115 |

| LGO12028A-063 | 0.63″ | 120 x 28 | White | 21.54 x 6.62 x 1.22 | 15.58 x 3.62 | I2C | SSD1312 |

| LGO6448A-066 | 0.66″ | 64 x 48 | White | 18.46 x 18.1 x 1.25 | 13.42 x 10.06 | I2C, SPI, 8-bit Parallel | SSD1315 |

| LGO9616A-069 | 0.69″ | 96 x 16 | White | 26.3 x 8.0 x 1.2 | 17.26 x 3.18 | I2C | SSD1315 |

| LGO12864C-077 | 0.77″ | 128 x 64 | White | 12.13 x 23.6 x 1.2 | 9.26 x 17.26 | SPI (4-wire) | SSD1312 |

| LGO80128A-078 | 0.78″ | 80 x 128 | White | 12.13 x 23.6 x 1.25 | 9.68 x 17.26 | I2C, SPI (4-wire) | SH1107 |

| LGO9639A-083 | 0.83″ | 96 x 39 | White, Blue | 23.8 x 16.2 x 1.3 | 19.37 x 7.86 | I2C, SPI (4-wire), 8-bit Parallel | SSD1306 |

| LGO12832B-087 | 0.87″ | 128 x 32 | White | 29.0 x 8.8 x 1.22 | 22.38 x 5.58 | I2C | SSD1312 |

| LGO12832A-091 | 0.91″ | 128 x 32 | White, Blue | 38.0 x 12.0 | 24.38 x 7.58 | I2C | SSD1306 |

| LGO9664A-095 | 0.95″ | 96 x 64 | White | 24.8 x 17.32 x 1.28 | 20.14 x 13.42 | I2C, SPI, 8-bit Parallel | SH1106 |

| LGO12864A-096 | 0.96″ | 128 x 64 | White, Blue, Yellow/blue | 27.5 x 27.8 | 23.74 x 12.86 | I2C | SSD1306 |

| LGO12864B-096 | 0.96″ | 128 x 64 | White, Blue, Yellow/blue | 27.3 x 27.8 | 23.74 x 12.86 | I2C, SPI | SSD1306 |

| LGO64128A-109 | 1.09″ | 64 x 128 | White | 14.0 x 31.96 x 1.2 | 10.86 x 25.58 | I2C, SPI | SSD1312 |

| LGO9696A-110 | 1.10″ | 96 x 96 | White | 25.49 x 29.1 x 1.45 | 19.655 x 19.655 | I2C, SPI, 8-bit Parallel | SH1107 |

| LGO12864D-129 | 1.29″ | 128 x 64 | White | 32.42 x 21.36 x 1.43 | 29.42 x 14.7 | I2C, SPI, 8-bit Parallel | SSD1315 |

| LGO12864A-130 | 1.30″ | 128 x 64 | White, Blue | 35.4 x 33.5 | 31.42 x 16.7 | I2C | SH1106 |

| LGO12864B-130 | 1.30″ | 128 x 64 | White, Blue | 35.4 x 33.5 | 31.42 x 16.7 | I2C, SPI | SH1106 |

| LGO12896A-132 | 1.32″ | 128 x 96 | White | 32.5 x 29.0 x 1.61 | 26.86 x 20.14 | I2C, SPI, 8-bit Parallel | SSD1327 |

| LGO128128A-150 | 1.50″ | 128 x 128 | White | 33.9 x 37.3 x 1.45 | 26.86 x 26.86 | I2C, SPI, 8-bit Parallel | SH1107 |

| LGO12864B-154 | 1.54″ | 128 x 64 | White, Blue, Yellow | 42.4 x 38.0 | 37.05 x 19.51 | I2C, SPI | SSD1309 |

| LGO12832D-205 | 2.05″ | 128 x 32 | White | 55.6 x 21.8 x 1.45 | 50.538 x 12.618 | I2C, SPI (4-wire), 8-bit Parallel | SSD1309 |

| LGO25664A-208 | 2.08″ | 256 x 64 | White | 62.5 x 20.6 x 1.63 | 51.18 x 12.78 | I2C, SPI, 8-bit Parallel | SH1122 |

| LGO12832C-223 | 2.23″ | 128 x 32 | White, Blue | 63.2 x 43.1 | 60.0 x 18.0 | I2C, SPI | SSD1305 |

| LGO25696A-225 | 2.25″ | 256 x 96 | White | 61.1 x 26.15 x 1.8 | 53.0 x 21.7 | SPI (4-wire) | SP5110 |

| LGO12864B-242 | 2.42″ | 128 x 64 | White, Blue, Yellow, Green | 71.0 x 43.5 | 57.0 x 29.5 | I2C, SPI | SSD1309 |

| LGO30496A-245 | 2.45″ | 304 x 96 | White, Blue, Amber | 72.0 x 28.2 x 1.4 | 59.26 x 19.18 | I2C, SPI, 8-bit Parallel | SH1126 |

| LGO12864F-270 | 2.70″ | 128 x 64 | Green | 73.0 x 40.24 x 2.0 | 61.41 x 30.69 | SPI, 8-bit Parallel | SSD1327 |

| LGO25664B-280 | 2.80″ | 256 x 64 | White, Blue, Green, Yellow | 84.0 x 25.8 x 2.0 | 69.104 x 17.264 | SPI (4-wire), 8-bit Parallel | SSD1322 |

| LGO25664C-312 | 3.12″ | 256 x 64 | White, Blue, Yellow, Green | 88.0 x 27.8 x 2.0 | 76.78 x 19.18 | SPI, 8-bit Parallel | SSD1322 |

| LGO240128A-337 | 3.37″ | 240 x 128 | White, Green, Yellow | 89.52 x 54.41 x 2.05 | 75.58 x 40.3 | SPI, 8-bit Parallel | SSD1322 |

| LGO25664D-550 | 5.50″ | 256 x 64 | Green | 146.0 x 45.0 x 2.0 | 135.65 x 33.89 | SPI, 8-bit Parallel | SSD1322 |

Request A Quote For More Details

Custom Graphic OLED Solution

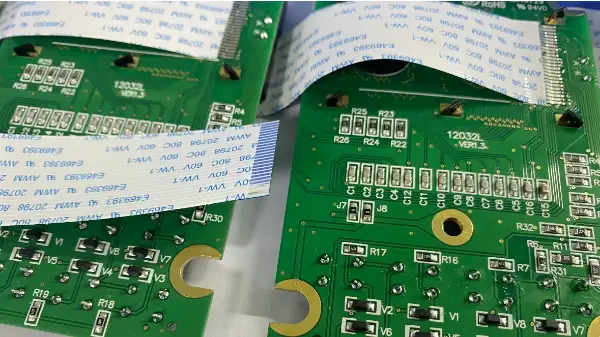

Cable

Modify your cables' length, orientation, and pinout, or add extra connections. Invest in a cable solution that is specifically made to simplify and safeguard your connections.

Interface

To choose the ideal interface for your project, choose from a large range of possibilities or consult with our specialists. To fulfill your design objectives, we can integrate 6800, SPI, I2C, RS232 and more into your display.

Connector

To suit the needs of your application, you may easily adjust any connection on your display. Our engineers can solder any type of header that your display may need, including boxed, right angle, and pin headers.

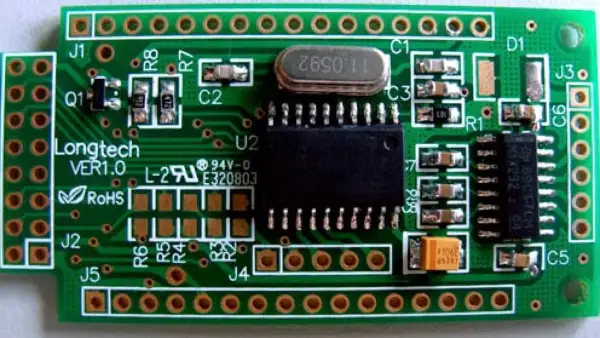

PCB

Choose from a variety of alterations to your PCB's design, size, pinout, and component arrangement to make it a perfect match for your application.

Custom OLED Solution

We have total control over the design, production, and quality control procedures for our display products. Our engineers will collaborate with you to create a prototype to validate and test your idea.

Are you looking for a unique display solution?

All You Need To Know About OLED

What is OLED?

OLED, or Organic Light Emitting Diodes, represents a significant leap in display technology. Unlike traditional LCDs, which require a backlight, OLED displays are made from organic compounds that emit light when electricity is applied. This key difference leads to superior image quality, offering deeper blacks, more vibrant colors, and improved viewing angles.

Longtech’s OLED display are available in three mechanical structures include COB, COG and COF passive matrix technology. The graphic OLED display in the Longtch product range have on-board controllers and interfaces include parallel, serial, and I2C OLED, SPI OLED. These OLED display modules have driven voltages of 3V, or 5V depending on resolution and color.

This article provides you with everything you need to know about OLED. What you’ll learn includes the uses of OLED, its parts, the mechanism behind how it works. In the later end, you can check the difference between the small factories and us.

- Superior Contrast

OLED displays offer unparalleled contrast ratios, rendering deep blacks and vibrant colors for outstanding image quality.

- High Brightness

With their self-emissive properties, OLEDs provide high levels of brightness, making them visible even in direct sunlight.

- Wide Viewing Angles

OLEDs maintain color accuracy and image quality from all viewing angles, ensuring an optimal viewing experience.

- Energy Efficiency

OLEDs consume less power when displaying darker content, making them energy-efficient for applications with predominantly dark user interfaces.

- Thin and Lightweight

OLEDs are remarkably thin and lightweight, making them ideal for sleek, modern designs in wearable tech and portable devices.

- Durability

OLEDs are known for their durability and longevity, providing a reliable display solution for a wide range of applications.

What Are OLEDs Used For?

OLEDs are present in almost all industries that need display. These could be the following:

- Instrument

- Industry Machinery Equipment

- Electrical Home Appliances

- Consumer Electronics

- White Goods

- POS System

- Home Applications

- Industrial Instrument

- Automation

- Audio/Visual Display Systems

- Medical Devices

How To Select the Best OLED Display For Your Application

It is not easy to introduce all aspects of selecting the best OLED display, so we have prepared a lot of information on this page for you to delve into. To make sure you can find the information you want quickly, we have prepared this content directory that will jump to the corresponding location when you click on it.

OLED Display Technology

OLED displays are brighter, have greater contrast, faster reaction times, broader viewing angles, and consume less power than traditional LED or LCD displays. OLED displays are self-illuminating, therefore they do not require a backlight to ensure optimal visibility in all settings. This allows OLEDs to be much thinner than traditional LED or LCD displays.

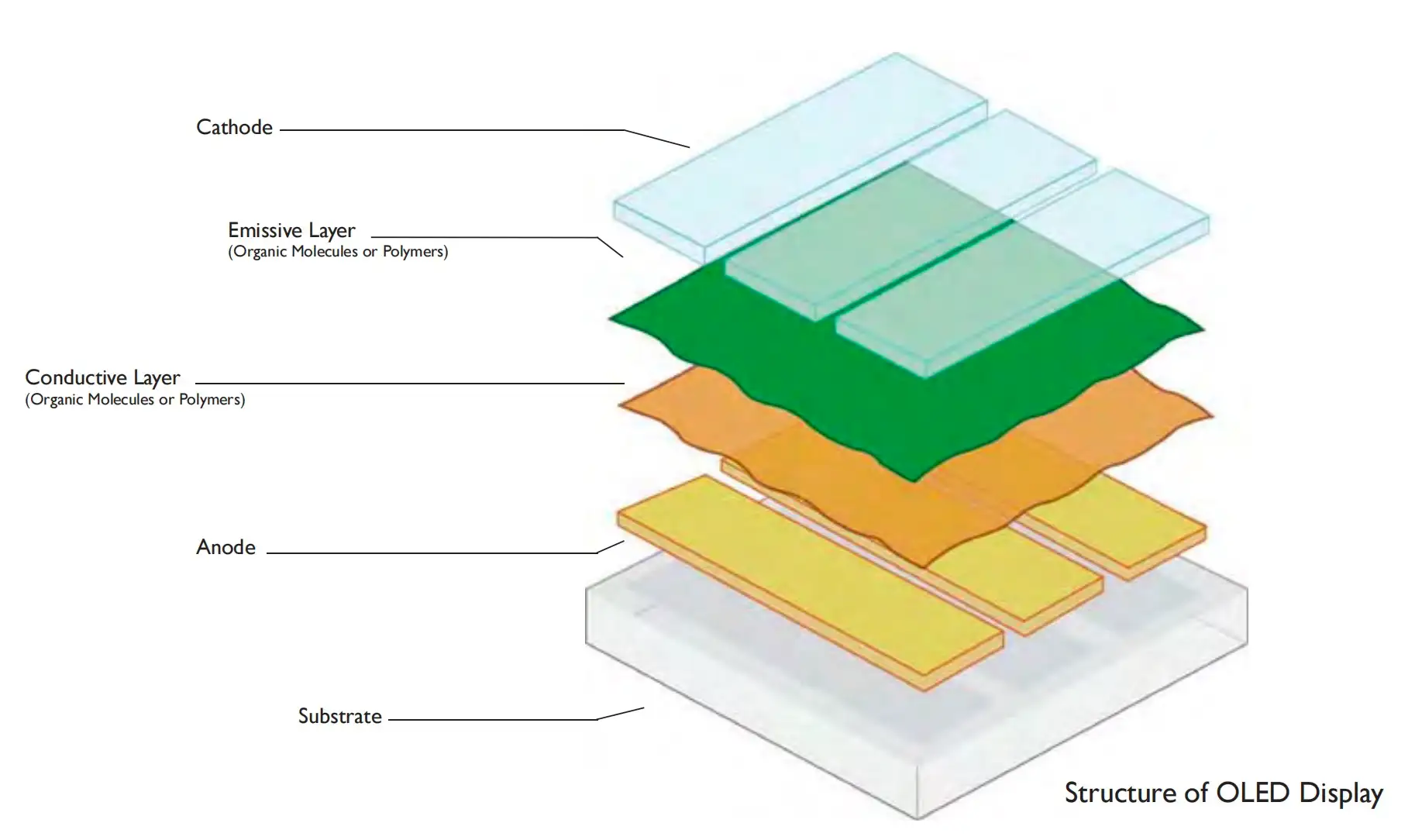

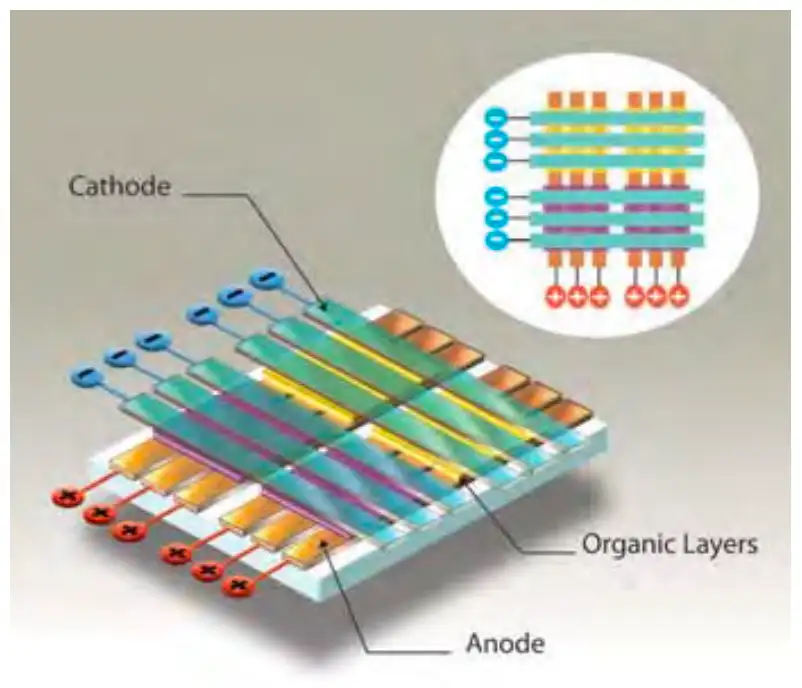

How Does OLED works?

OLED displays are composed of a layer of organic material sandwiched between two conductors. The anode and cathode are then sandwiched between a glass top plate (seal) and a glass bottom plate (substrate).

When an electric current is placed between the two conductors, the organic material emits a strong electroluminescent light. When energy travels from the negatively charged layer (cathode) to the other (anode) layer, it stimulates the organic material between the two, causing light to be seen through the outermost layer of glass.

How Color Is Produced?

To produce color on OLED displays, an electric current is required to stimulate the relevant pixels. The cathodes and anodes are arranged perpendicularly to form pixels. Light is emitted when the cathodes and anodes meet. The electric current delivered to the specified strips of anodes and cathodes determines which pixels are turned on and which are left off. The brightness of each pixel is proportional to the applied current.

OLED Display: Size and Resolution

Size and resolution are not just specifications. They are the essence of user experience and functionality. Longtech’s array of OLED display sizes, ranging from the compact 0.49″ to the more substantial 3.12”, caters to a broad spectrum of applications. Paired with resolutions from 64×32 to 256×64 pixels, these displays provide the flexibility to match every specific need, ensuring optimal clarity and usability in various contexts.

Compact Displays (0.49″ to 1.5″)

- Ideal for Wearable Tech and Portable Devices: The smaller OLED screens are perfect for applications where space is at a premium, like smartwatches or medical monitoring devices. Their compactness does not compromise the quality, offering sharp and clear visuals in a small package.

- Benefits: Enhanced portability, lower power consumption, and suitability for continuous wear or use.

Larger Displays (1.5″ to 3.12″)

- Perfect for Control Panels and Consumer Electronics: Larger OLED displays are well-suited for products requiring more detailed information display, such as automotive dashboards, high-end audio systems, or home automation controls.

- Benefits: Increased screen real estate for more detailed information, better user interaction, and suitability for complex graphical interfaces.

Lower Resolutions (64×32, 128×32)

- Suitable for Simple Display Needs: These resolutions are ideal for applications where basic visual representation suffices. This includes simple user interfaces, basic data displays, or devices where the primary function is not display-centric.

- Impact: Cost-effective, energy-efficient, and sufficient for displaying basic text and graphics.

Higher Resolutions (128×64, 256×64)

- For Detailed and Intricate Displays: Higher resolutions are essential for applications where detail is key. This includes medical devices, high-quality consumer electronics, and industrial control systems where precision and clarity are paramount.

- Impact: Enhanced visual appeal, the ability to display complex images and texts with greater clarity, and improved user engagement.

At Longtech, we understand that the right size and resolution of an OLED display can make a significant difference in the final product. Our diverse range of sizes and resolutions ensures that whether you need a display for a compact wearable or a detailed control panel, we have the perfect solution for you.

OLED Display: Monochrome Color

The choice of color in monochrome OLED displays is not just an aesthetic decision; it has practical implications. Each color offers unique advantages. By offering these color options, Longtech caters to a wide range of applications, ensuring that each display is not only functional but also aesthetically pleasing.

White

The most versatile color, offering maximum contrast against any background.

Blue

Known for its modern, high tech feel, blue OLEDs are popular in consumer electronics.

Blue/Yellow

A striking blend of warm yellow and cool blue for clear, intuitive displays.

Yellow

This warm color is easier on the eyes, making it suitable for low-light environments.

Green

Known for its calming effect, green is ideal for displays that need to be constantly monitored.

OLED Display: Structure

In the realm of OLED displays, two primary structures dominate the scene: COG (Chip on Glass) and COF (Chip on Film), each with its unique advantages and applications.

What is Chip-on-Glass (COG)?

COG, or Chip on Glass, is a method where the microchip is directly mounted on the glass of the OLED display. This approach is known for its space efficiency and improved display quality. But what makes COG so special in the world of OLED displays?

- Reduced Size and Weight: By eliminating the need for separate circuit boards, COG displays are thinner and lighter.

- Enhanced Image Quality: Direct bonding reduces parasitic inductance and capacitance, enhancing signal integrity.

- Improved Reliability: Fewer interconnections mean fewer potential points of failure.

How Does COG Combined with PCB and Frame Enhance OLED Displays?

While COG offers distinct advantages, combining it with a Printed Circuit Board (PCB) and a frame takes these displays to the next level. But how does this combination work, and what benefits does it bring to the table?

The integration of COG with PCB and a frame results in a robust and stable OLED display unit. This combination not only reinforces the physical structure but also improves connectivity and ease of integration into various devices.

This fusion of COG, PCB, and frame creates a holistic solution that addresses both aesthetic and functional needs, making it a go-to choice for many industrial and consumer applications.

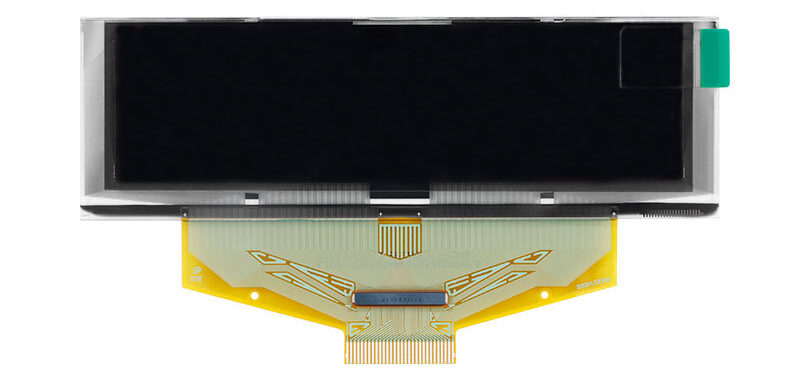

What is Chip-on-Film (COF)?

On the other side of the spectrum lies the COF, or Chip on Film, structure. This technique involves attaching the microchip to a flexible film, which is then connected to the OLED display. But what are the unique benefits of the COF structure?

- Flexibility: COF displays can be bent or curved, making them ideal for innovative design applications.

- Scalability for Large Displays: COF can support larger display sizes more effectively than COG.

- Heat Dissipation: The film substrate helps in better heat dissipation, which is crucial for larger displays.

Why is COF Combined with PCB and Frame a Game Changer?

Just like COG, COF also benefits significantly when combined with PCB and frame. But what extra advantages does this combination offer, especially in the context of COF’s inherent flexibility?

Combining COF with PCB and frame not only reinforces the structure but also enhances its design flexibility. This integration allows for more robust, yet still flexible and lightweight OLED displays, suitable for a wide range of applications.

This combination is particularly beneficial for products that require both durability and a degree of flexibility, striking a perfect balance between robustness and design versatility.

COG vs COF

| Feature | COG | COF |

|---|---|---|

| Flexibility | Limited | High |

| Size Suitability | Smaller Displays | Larger Displays |

| Integration | Direct on Glass | On Flexible Film |

| Application | Compact Devices | Innovative, Large Displays |

The choice between COG and COF structures in OLED displays depends largely on the application requirements. For compact, high-resolution devices, COG offers a reliable and efficient solution. In contrast, COF comes into play for larger, more flexible display needs. Both structures, when enhanced with PCB and frame, offer additional stability and ease of integration, making OLED technology versatile and adaptable to various innovations in display technology.

Request A Quote For More Details

Why Choose OLED Display From Longtech?

Diverse Product Line

With a broad array of LCD and OLED solutions, we cater to every tech requirement.

Unwavering Quality

Our products meet international standards, embodying top-tier quality and consistency.

Competitive Pricing

High quality meets affordability in our competitively priced products.

Low MOQ

Our production is flexible and will meet your requirement of ordering varying quantities.

Exceptional Service

Our customer service team ensures a seamless, professional experience.

Trusted Partner

Clients trust us for our reliability and unwavering commitment to their success.

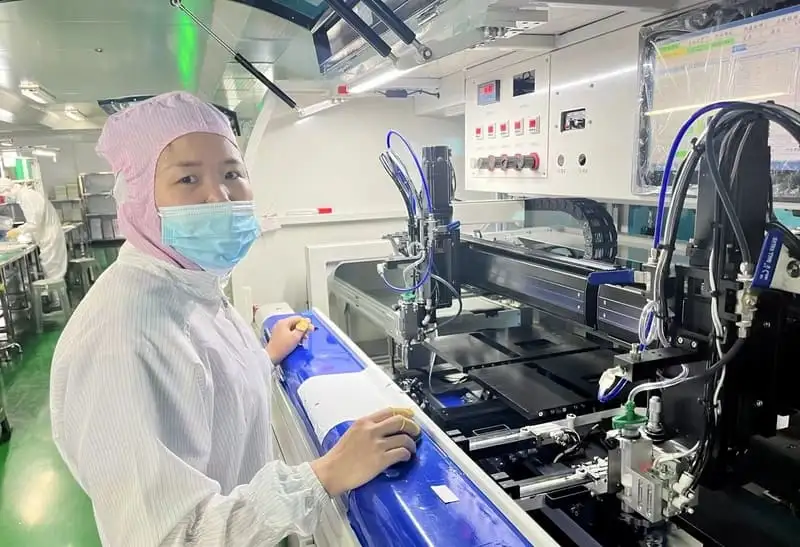

More Than Just an OLED Display Manufacturer

Superior in-house production ensures quality and efficiency, unlike small factories with higher defect rates.

Small Factories

Our Advantages

Small Factories

Our Advantages

Small Factories

Our Advantages

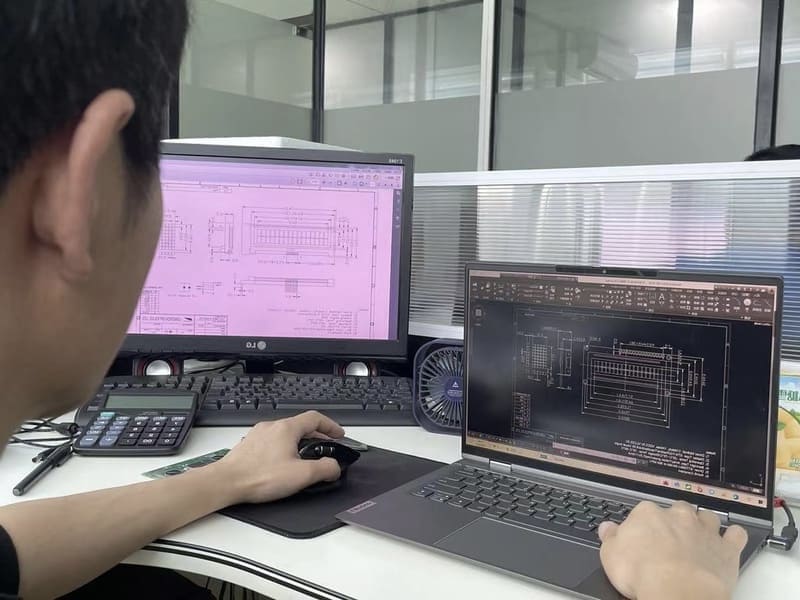

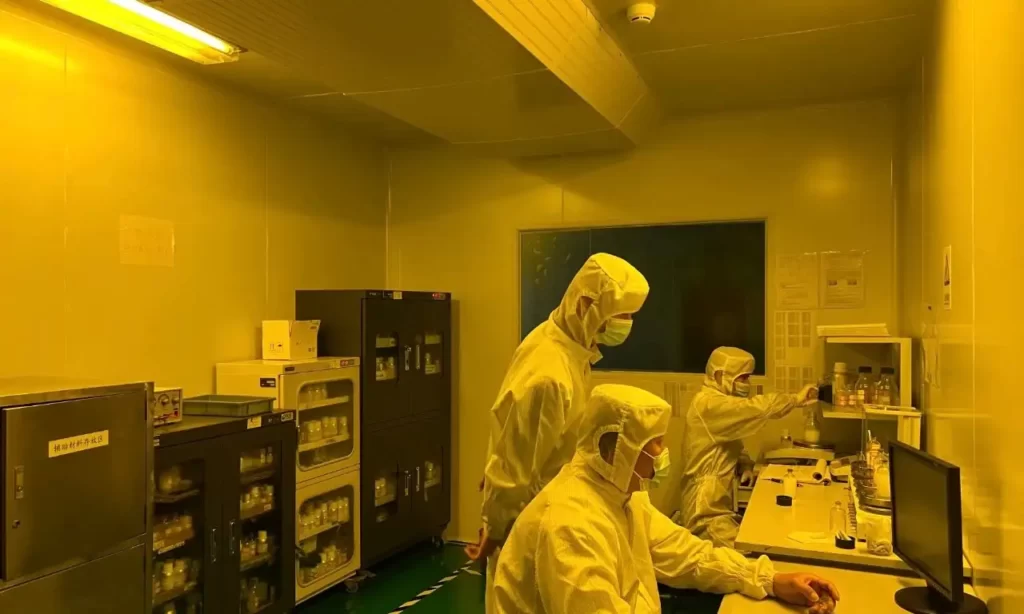

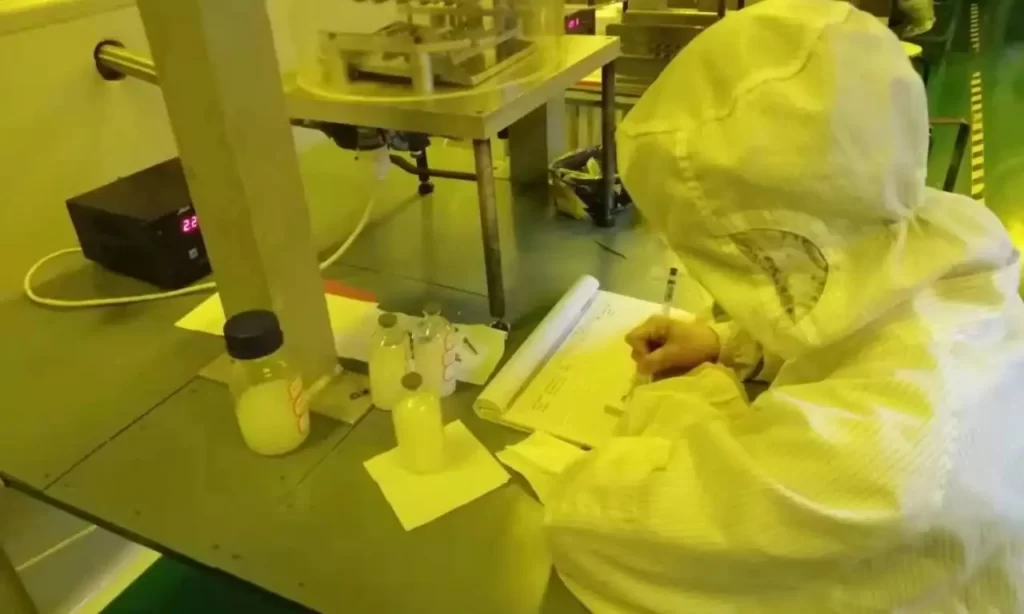

A Few Steps of Our Production Process

There are more than 30 steps for the production process of display and here only a few typical production steps are displayed.

Frequently Asked Questions

We have compiled the most frequently asked questions about our LCD display here for your convenience, but please feel free to contact us if you have any additional questions.

We offer detailed datasheets and technical guides for all our products. These resources provide comprehensive information to facilitate the integration of our LCDs into your design. Our expert team is also available to assist you with any specific queries or challenges you may face.

Longtech specializes in custom solutions. Our team can work closely with you to understand your unique requirements and develop a customized LCD product that perfectly fits your application.

Our LCDs come with various options for temperature range, contrast adjustment, and backlighting to ensure optimal display performance under different conditions. Our technical team can also provide guidance on how to select and configure these options based on your specific needs.

Yes, we provide libraries and sample code for most of our LCD products. These resources can help you get started quickly with programming the display for your application.

How do I diagnose and resolve issues with the LCDs?

At Longtech, quality is our top priority. We follow a strict quality control process which includes various stages of testing and inspection to ensure our products meet the highest standards.

Yes, we understand the need for testing before making a large purchase. Please contact our sales team to discuss the minimum order quantity for your chosen product.

Lead times can vary depending on the complexity of the customization and the quantity required. Our team will provide a more precise timeline once the specifications are finalized.

We have extensive experience in global shipping and can coordinate logistics to any part of the world. Our team can work with you to determine the best shipping method based on your location, budget, and timeline.

Absolutely, our commitment to our customers doesn't end after a sale. We provide ongoing technical support to ensure the successful integration and operation of our products in your application.

We stand by the quality of our products. In the unlikely event that you receive a defective product, please contact us immediately, and we will work to address and rectify the issue promptly.

Request an Instant Quote for Your Projects!

If you’ve got LCD display concerns and specific requirements, it’s time to speak to one of our Industry Experts. We’re glad to answer any questions you may have!

Message us, we will be in touch shortly

LONGTECH DISPLAY

- Address: 5F No.8-5 Xiayang Road, Haicang Area, Xiamen China

- Email: zhong@longtech-display.com

- Tel: +0086-592-6060928

- Fax: +0086-592-6682033

*We respect your confidentiality and all information is protected.