The journey of LCD glass from its conceptual beginnings to its ubiquitous presence in modern life is a story of innovation and technological advancement. This blog post seeks to explore the origins, development, and intricate manufacturing processes behind LCD glass, a key component in our digital displays.

LCD glass is a marvel of modern engineering, pivotal in shaping the way we experience digital technology. Its unique composition, involving liquid crystals sandwiched between conductive layers, allows for the vibrant and efficient displays we’ve come to rely on. This post dives deep into the history and manufacturing process of LCD glass, revealing the complexities and innovations that drive this essential technology.

Embark on this informative journey to understand the roots of LCD glass, tracing its evolution from a scientific curiosity to a cornerstone of contemporary display technology.

How Did LCD Technology Evolve?

The development of LCD technology is a fascinating journey of scientific discovery and engineering innovation. From its inception in the 19th century to becoming an indispensable part of modern electronic displays, LCD technology’s evolution is a testament to human ingenuity and persistence.

Historical Background

Discovery of Liquid Crystal Materials

The story of LCD glass begins in the late 19th century with Friedrich Reinitzer’s discovery of liquid crystals. This groundbreaking discovery marked the first step towards understanding the unique properties of these materials, which exhibit characteristics of both liquids and solids. This initial discovery sparked a wave of research and exploration into the potential applications of liquid crystals, paving the way for their use in display technology.

- Unique Characteristics: Liquid crystals are substances that exhibit a phase of matter that has properties between those of conventional liquids and solid crystals. Reinitzer’s discovery of these properties in cholesterol compounds extracted from carrots was a significant milestone.

- First Observations: Reinitzer observed that these compounds exhibited two distinct melting points and color changes, indicating different states of matter. These observations were crucial in understanding the dual nature of liquid crystals and their potential applications.

Development of LCD Applications

The practical application of liquid crystals in display technology began to materialize several decades after their discovery. The 1970s marked a significant era in this journey, with the development of the twisted nematic (TN) field effect, which became the foundation for modern LCD displays.

- Twisted Nematic (TN) Field Effect: This technology involves aligning liquid crystal molecules in a specific pattern that can be altered by applying an electric field. This ability to control the alignment of molecules made it possible to modulate light and create images on a screen, a principle that is fundamental to LCD technology.

- Commercialization: The advent of TN technology enabled the development of the first LCD-based consumer products. This era saw the introduction of LCD watches and calculators, showcasing the practical applications of liquid crystals in everyday technology.

Learn more about What is the Chemical Composition of LCD Glass?

What Goes Into Making LCD Glass?

The creation of LCD glass is a complex and sophisticated process, blending high-quality materials and precision engineering. This section delves into the intricate steps involved in manufacturing LCD glass, from raw material selection to the assembly of the final product.

LCD Glass Production

Primary Function as a Light Valve

At the core of LCD technology is the ability of LCD glass to function as a light valve. This involves the control of light passage through the alignment of liquid crystal molecules sandwiched between polarized layers. The orientation of these molecules changes in response to electric currents, allowing for the precise manipulation of light. This process is essential for creating the clear and dynamic images seen on LCD screens.

- Alignment of Molecules: The precise orientation of liquid crystal molecules is a critical factor in the functionality of LCD displays. This alignment determines how light is modulated and transmitted through the screen, affecting the clarity, color, and contrast of the display.

- Electric Currents and Light Control: Applying electric currents to liquid crystal molecules enables the dynamic control of light passage through the display. This ability to manipulate light at a molecular level allows for the creation of high-resolution, energy-efficient displays.

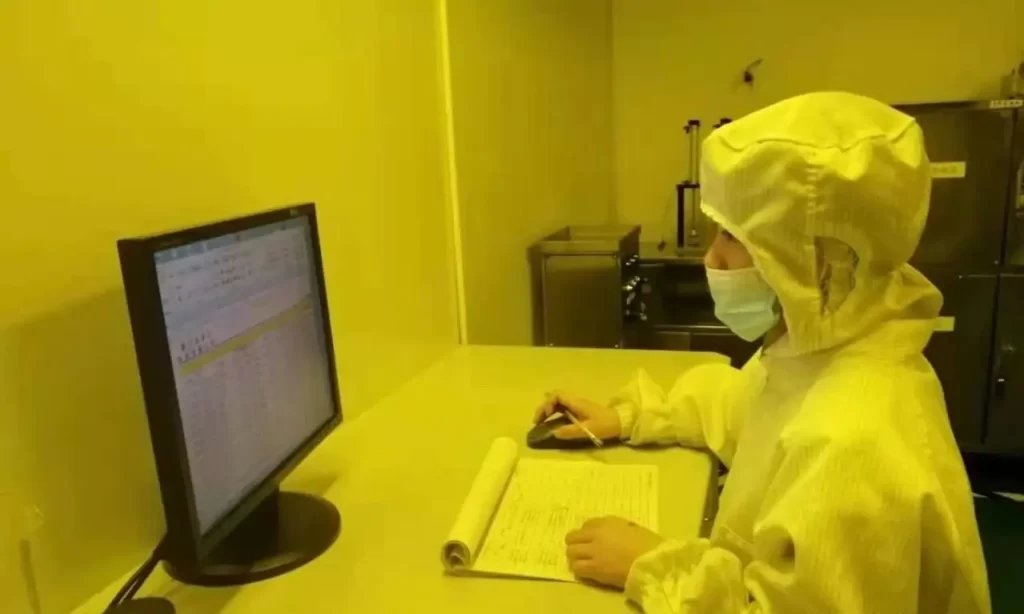

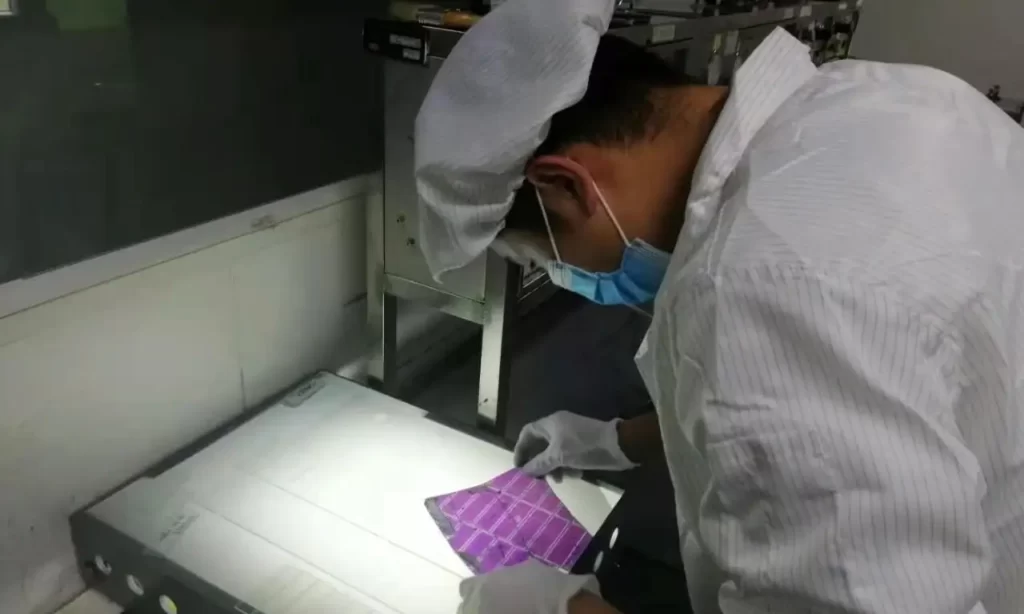

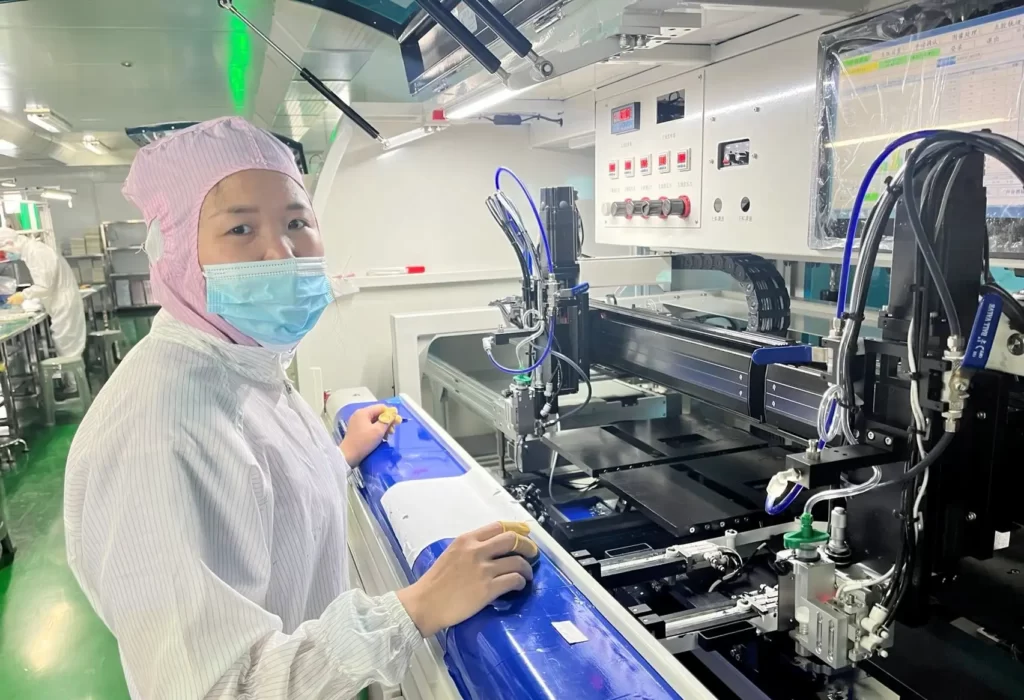

Materials and Manufacturing Process

The manufacturing of LCD glass is a multi-step process that requires precision and expertise. It begins with the selection of high-purity materials and involves sophisticated techniques to construct the various layers that constitute an LCD screen.

- High-Purity Silica Sand: The production process starts with melting high-purity silica sand to create a clear, uniform glass substrate. This glass forms the base layer of the LCD screen, providing a transparent and stable surface for subsequent coatings and assemblies.

- Indium Tin Oxide (ITO) Coating: The glass substrate is coated with a thin layer of indium tin oxide, a transparent conductor that forms the electrodes of the LCD. This coating is crucial for the application and control of electric currents across the liquid crystal layer.

- Assembly of Layers: The final step in LCD glass production is the assembly of various layers, including the liquid crystal layer, polarizing filters, and color filters. This assembly process is meticulously controlled to ensure that each layer aligns correctly and functions as intended.

Technological Advancements in LCD Displays

The 1980s and 1990s were pivotal decades for LCD technology, witnessing significant advancements that drastically improved display quality and functionality. These years saw the introduction of new manufacturing techniques and material innovations, setting the stage for the modern LCD screens we use today.

Pioneering Advancements in the 80s and 90s

- Enhanced Display Quality: During this period, researchers focused on improving the contrast, color reproduction, and response times of LCD displays. Innovations in liquid crystal materials and alignment techniques contributed to sharper, more vibrant displays.

- New Manufacturing Techniques: The development of advanced manufacturing processes, such as photolithography and etching, allowed for the production of finer, more precise LCD components, paving the way for high-resolution displays.

Emergence of Flexible and 3D Displays

- Flexible Displays: The advent of new materials and manufacturing processes enabled the creation of flexible LCD displays. These bendable screens opened up new possibilities for wearable technology and innovative gadget designs.

- 3D Displays: The development of 3D LCD technology, which does not require special glasses, marked another significant advancement. This technology relies on sophisticated algorithms and display techniques to create a three-dimensional viewing experience.

The Future of LCD Glass

As we look towards the future, the LCD industry continues to evolve, driven by ongoing research and technological innovation. The next generation of LCD displays promises even greater efficiency, functionality, and versatility.

Upcoming Trends and Technologies

- Thinner, More Energy-Efficient Displays: Future LCD screens are likely to be even thinner and more energy-efficient, thanks to advancements in materials and backlighting technologies.

- Integration of AI and IoT: The integration of artificial intelligence (AI) and the Internet of Things (IoT) with LCD technology is set to transform the user experience, enabling smarter, more interactive displays.

Ongoing Evolution of LCD Technology

- Sustainable Manufacturing: There is a growing emphasis on eco-friendly manufacturing processes and materials in the LCD industry, aligning with global sustainability goals.

- Advanced Functionalities: We can expect to see LCDs with enhanced functionalities, such as improved touch responsiveness, higher refresh rates, and better ambient light adaptation.

Conclusion

The journey of LCD glass from its humble beginnings to its present-day prominence is a testament to the relentless pursuit of innovation in the field of display technology. As we continue to witness and benefit from these advancements, the future of LCD glass remains bright, promising even more sophisticated and user-friendly displays. The story of LCD technology is far from over; it is an ever-evolving narrative of human ingenuity and technological progress.