Ever glanced at a digital billboard or your smartphone screen and wondered how these vibrant displays come to life? It’s all thanks to the magic of LCD technology. But what if I told you that creating a custom LCD display, tailored to your specific needs or project, is within your reach? Whether you’re a budding electronics manufacturer or just a tech enthusiast, this comprehensive guide will walk you through the mesmerizing world of custom LCD displays from design, manufacture, to application.

Getting Started: The ABCs of LCDs

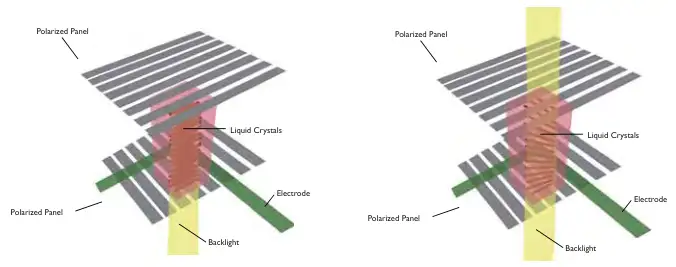

Before diving deep into the intricacies of custom LCD displays, it’s crucial to get the basics straight. LCD stands for Liquid Crystal Display. It’s a flat-panel display technology commonly used in TVs, computer monitors, smartphones, and a myriad of other devices. The secret behind its operation lies in the manipulation of light through liquid crystals – hence the name.

But what makes LCD technology so appealing, especially for custom projects? Here are a few pointers:

- Versatility: LCDs can be made to fit any size, shape, or resolution requirement.

- Energy Efficiency: They consume significantly less power compared to other display technologies, like CRTs(Cathode ray tube) or plasma.

- Quality: LCDs offer excellent image quality with sharp, clear pictures and high resolution.

So, whether you’re designing a handheld device, a piece of industrial equipment, or anything in between, LCDs offer a flexible and efficient solution.

Diving Deeper: Designing Your Custom LCD

Designing a custom LCD goes beyond picking the right size and resolution. It involves a thorough understanding of your project’s specific needs and how different aspects of LCD technology can meet those needs.

Understanding Your Requirements

The first step is to clearly define what you need from your custom LCD display. Consider the following:

- Size and Aspect Ratio: Will it be a compact screen for a wearable or a large display for digital signage?

- Resolution and Color Depth: How much detail does the display need to show? Will it display intricate graphics or simple text?

- Viewing Angle: From which angles will the display be viewed? Does it need to be visible from side viewpoints?

- Durability and Environment: Will the display be used outdoors and need to withstand harsh weather, or will it be used indoors?

Answering these questions forms the foundation of your LCD design process.

Choosing the Right Type of LCD

Once you have a clear understanding of your requirements, it’s time to choose the type of LCD that best fits your project:

- TN (Twisted Nematic) LCDs:TN displays are the cornerstone of LCD technology, offering fast response times and affordability. Ideal for basic applications requiring speed and efficiency.

- STN (Super Twisted Nematic) LCDs:STN technology enhances the viewing angles and display quality compared to TN. It’s suitable for devices where readability in indirect light is crucial.

- FSTN (Film-compensated Super Twisted Nematic) LCDs:FSTN displays improve upon STN with a film compensator, offering superior contrast and visibility. A top choice for outdoor or high-ambient light conditions.

- COG (Chip On Glass) LCDs:COG technology involves mounting the LCD driver or controller directly on the glass substrate, allowing for thinner, more compact displays. Perfect for sleek, modern applications.

- VA (Vertical Alignment) LCDs:VA LCDs boast high contrast ratios, deep blacks, and wide viewing angles. They’re preferred in high-end displays where image quality cannot be compromised.

- TFT (Thin Film Transistor) LCDs:TFT displays provide the best color, contrast, and response times. They’re essential for multimedia applications and high-resolution requirements.

- OLED (Organic Light Emitting Diodes) Displays:OLED technology offers self-illumination, eliminating the need for backlighting. This results in thinner displays with more vivid colors and true blacks.

Each type has its pros and cons, so picking one over the other depends on what aspect you prioritize more: speed, color accuracy, or contrast.

The Manufacture Maze

With your design specs in hand, it’s time to make your custom LCD come to life. But, as you might guess, this is where things get a tad more complicated. Let’s simplify it.

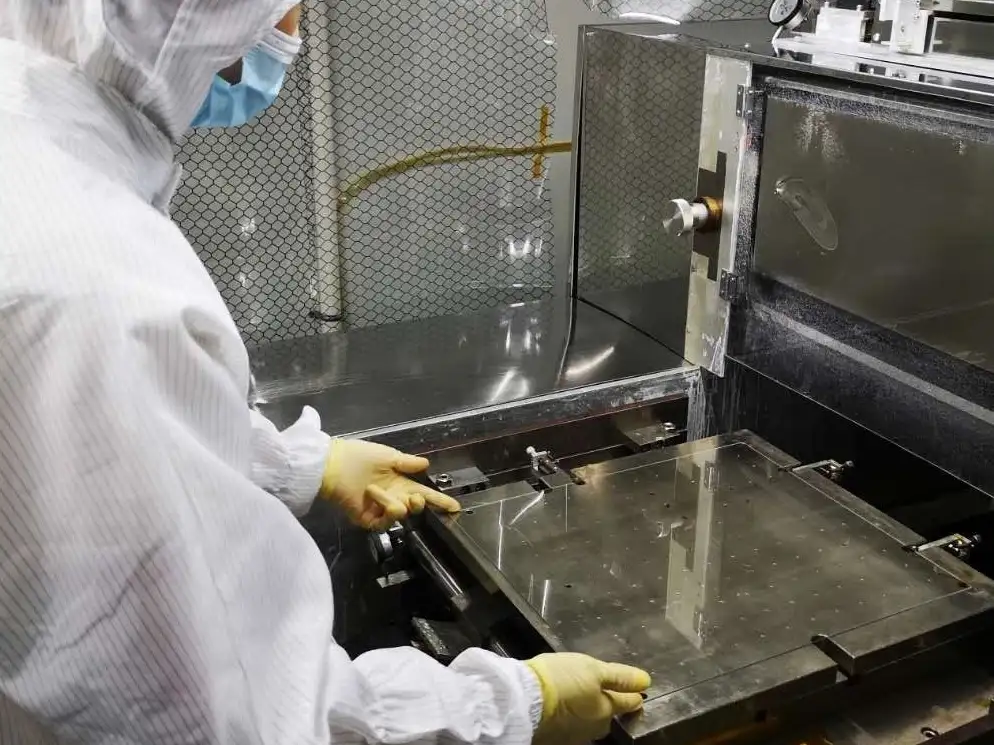

Prototyping

Creating a prototype is the first practical step in manufacturing your custom LCD. This involves:

- Drafting Design Files: Creating detailed CAD drawings that outline every aspect of your design.

- Selecting Materials: From the glass to the liquid crystals, every material must be chosen carefully to meet your display’s specifications.

- Assembly: Putting all components together to create a working prototype.

Testing and Tweaking

Your prototype will need to go through rigorous testing to ensure it meets all your requirements. This might reveal some necessary adjustments or improvements before moving on to mass production.

Mass Production Considerations

When transitioning from prototype to mass production, keep these factors in mind:

- Cost-Effectiveness: Larger production runs usually lower the cost per unit, but initial investment is higher.

- Quality Control: Ensuring every unit meets your standards is crucial, especially as production scales.

- Lead Times: Be realistic about manufacturing timelines. Rushing can impact quality.

Bringing LCDs to Life: The Magic of Backlights and Controllers

An LCD by itself cannot generate light. This is where backlights and controllers come into play, illuminating your display and bringing it to life.

The Role of Backlights

Backlights are used to illuminate the LCD from behind (hence the name), making the display visible. LED backlights are the most commonly used due to their efficiency and longevity.

Controllers: The Brains Behind the Display

LCD controllers are the circuit boards that manage the interface between your display and the device it’s part of. They translate signals into images, text, or animations that appear on your screen. Choosing the right controller is as crucial as selecting the display itself.

Applications: The Sky’s the Limit

Custom LCD displays have a myriad of applications across various industries. From consumer electronics, like smartphones and smartwatches, to more niche applications like industrial control panels, automotive dashboards, and even medical devices, the versatility of LCDs is unparalleled.

The beauty of custom LCD displays is that they can be tailored to fit the unique demands of these applications, offering optimized performance, durability, and visibility.

Conclusion: Your Canvas Awaits

Embarking on the journey of creating a custom LCD display can be daunting, but it’s also incredibly rewarding. From sketching out your initial design to seeing your custom display in action, every step offers a unique blend of challenges and triumphs.

Remember, the key to a successful custom LCD display lies in meticulous planning, understanding your needs, and choosing the right partners to bring your vision to life. So why wait? Your canvas awaits, ready to be transformed into a breathtaking display that meets your exact specifications.

Whether you’re at the helm of an electronics manufacturing endeavor or just starting out, remember, with custom LCD displays, the only limit is your imagination.