In today’s fast-paced world, where visual displays dominate in both personal and professional settings, the role of Liquid Crystal Display (LCD) technology has become increasingly significant. From smartphones and televisions to industrial monitors and automotive displays, LCDs are ubiquitous, offering crisp, clear images. But what lies at the heart of these sophisticated displays? The answer is deceptively simple yet intriguingly complex – it’s the LCD glass.

LCD glass, or Liquid Crystal Display glass, is composed primarily of Silicon dioxide (SiO2), Aluminum oxide (Al2O3), and Sodium oxide (Na2O). These components are meticulously blended to create the clear, durable glass used in various display screens.

As we delve deeper into this topic, the intricate nature of LCD glass becomes apparent, revealing how its chemical composition is crucial to its functionality. This understanding not only satiates our curiosity but also underscores the importance of material science in advancing technology.

Basic Composition of LCD Glass: A Comprehensive Exploration

The chemical composition of LCD glass primarily includes silicon dioxide, aluminum oxide, and boron oxide, which are key for its thermal stability and resistance to thermal shock. This composition underpins the glass substrates, crucial for the display’s clarity and durability.

Silicon Dioxide (SiO2): The Cornerstone of Clarity

Unraveling the Role of Silicon Dioxide

Silicon dioxide, at its core, is the primary ingredient in the world of LCD glass, but its role extends far beyond being just a base material.

The Multifaceted Nature of Silicon Dioxide

- Architectural Strength: SiO2 provides a robust framework, ensuring the glass can withstand physical pressure and everyday handling, essential for devices ranging from smartphones to large-scale televisions.

- Purity and Clarity: The inherent purity of silicon dioxide is key to its optical clarity. This transparency is critical for accurate color representation and sharp image resolution, vital for high-definition displays.

- Environmental Fortitude: Its ability to resist environmental chemicals makes it an ideal choice for diverse settings, safeguarding the display against various elements.

Aluminum Oxide (Al2O3) and Sodium Oxide (Na2O): Enhancing Performance

Aluminum Oxide: The Durability Factor

Aluminum oxide might not be the star of the show, but its contribution to the durability of LCD glass is unparalleled.

Delving Deeper into Aluminum Oxide’s Role

- Scratch and Impact Resistance: Al2O3 adds a layer of resilience to the glass, protecting it against scratches and sudden impacts, which is particularly crucial for mobile devices and outdoor screens.

- Thermal Adaptability: This component enables the glass to adapt to temperature changes, maintaining performance in environments ranging from freezing outdoor displays to heated indoor settings.

Sodium Oxide: The Electrical Enhancer

Though less prominent, sodium oxide’s role in the electrical performance of LCD glass is significant.

Sodium Oxide’s Critical Contributions

- Improved Conductivity: Na2O enhances the electrical conductivity of the glass, which is essential for the quick response and efficiency of touchscreens and other interactive displays.

Additives: Fine-Tuning LCD Glass Properties

Barium Oxide (BaO): Strengthening Against the Elements

Barium oxide plays a vital role in enhancing the chemical durability of LCD glass.

The Protective Role of Barium Oxide

- Combatting Chemical Wear: BaO increases the glass’s resistance to chemical degradation, crucial for displays used in industrial and outdoor environments where exposure to harsh chemicals is common.

Magnesium Oxide (MgO): Elevating Optical Excellence

Magnesium oxide significantly enhances the optical properties and thermal stability of LCD glass.

The Optical Brilliance of Magnesium Oxide

- High-Definition Clarity: MgO is instrumental in achieving crystal-clear, high-definition displays, making it a key ingredient for ultra-high-definition screens.

- Consistent Performance Across Temperatures: Its ability to maintain stability across temperature variations ensures consistent display quality, from cold outdoor billboards to indoor screens in climate-controlled environments.

Boron Oxide (B2O3): Ensuring Uniformity and Stability

Boron oxide’s contribution to maintaining the thermal expansion coefficient of the glass is critical for the longevity and reliability of LCD displays.

Boron Oxide’s Balancing Influence

- Uniform Thermal Behavior: B2O3 ensures that the glass expands and contracts evenly, preventing internal stresses that could lead to cracks or other display issues, especially in larger screens.

Learn more about Is LCD a Glass or Plastic?

How is LCD Glass Manufactured?

The Manufacturing Process

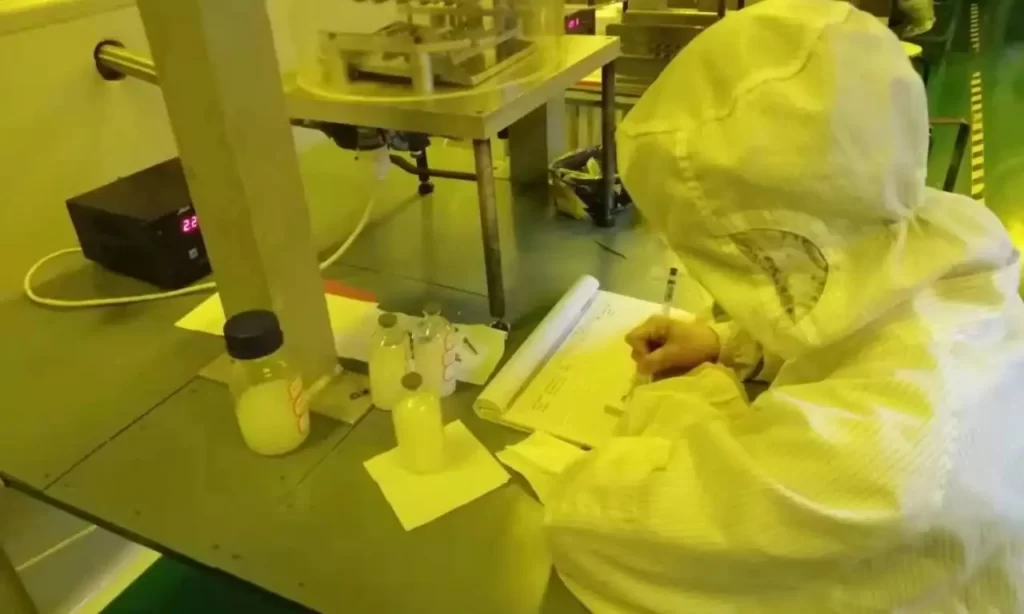

The process of manufacturing LCD glass is both intricate and precise, involving multiple steps that must be meticulously controlled to ensure the highest quality. The journey begins with the careful selection and blending of the raw materials: Silicon dioxide, Aluminum oxide, and Sodium oxide, along with the various additives like Barium oxide, Magnesium oxide, and Boron oxide.

These materials are then melted together at extremely high temperatures, a process that requires precise control to ensure uniformity in the glass’s composition. This molten glass is then cooled and formed into sheets, maintaining a consistent thickness crucial for display performance.

At Longtech, we’ve honed this process over the years, constantly refining our techniques to produce glass that meets the stringent demands of modern display technology.

Learn more about How to Make LCD Glass?

Emphasis on Chemical Processes

The chemical processes involved in manufacturing LCD glass are not just about combining materials; they involve a complex series of reactions and interactions. For instance, the way Silicon dioxide interacts with Aluminum oxide and Sodium oxide determines the structural integrity of the glass. Similarly, the additives like Barium oxide and Magnesium oxide play crucial roles in modifying the glass’s properties, such as its refractive index and thermal stability.

The Role of Each Component in LCD Glass

Silicon Dioxide: Ensuring Clarity and Insulation

Silicon dioxide’s primary role in LCD glass is to maintain transparency and provide electrical insulation. These features are essential for clear image reproduction and the safe operation of electronic devices. The high purity of silicon dioxide also contributes to the overall longevity and performance consistency of LCD screens.

Aluminum Oxide: Strength and Corrosion Resistance

Aluminum oxide’s incorporation into LCD glass imparts additional strength, making screens more resistant to physical stress and less prone to damage. Its chemical resistance properties also protect the screen from corrosive elements, ensuring a longer lifespan and maintaining display quality over time.

Borosilicate: Combatting Thermal Expansion

The inclusion of borosilicate in LCD glass addresses the issue of thermal expansion. By reducing the glass’s tendency to expand and contract with temperature changes, borosilicate helps maintain the integrity of the display, preventing warping or other damage that could compromise image quality.

Soda-Lime Glass: Balancing Cost and Performance

While not as advanced as other components, soda-lime glass offers a balance between cost and performance. It’s a practical solution for less demanding applications where high-end features like extreme temperature resistance or ultra-high clarity are not critical.

Advanced Additives in Modern LCD Glass

Strontium and Barium: Elevating Display Clarity and Color Fidelity

The inclusion of strontium and barium in modern LCD glass formulations is a testament to the ongoing innovation in display technology. These elements play a critical role in enhancing the optical properties of the glass, leading to improved display clarity and color fidelity.

Strontium and barium are used to manipulate the refractive index of the glass. The refractive index is a measure of how much light bends, or refracts, when entering a material. By adjusting this index, manufacturers can achieve greater control over the light passing through the LCD. This control leads to sharper images, with more precise detailing and vibrant colors. These enhancements are particularly noticeable in high-definition displays, where clarity and color accuracy are paramount.

Learn more about Do I Need to Protect LCD Glass?

Rare Earth Elements: Advancing Light Transmission and Energy Efficiency

Rare earth elements, such as neodymium and erbium, are increasingly being integrated into LCD glass formulations to improve light transmission and energy efficiency. These elements have unique optical properties that allow them to modify the way light interacts with the glass. By incorporating rare earth elements, manufacturers can increase the amount of light that passes through the LCD, reducing the need for additional backlighting.

This increase in light transmission not only enhances the brightness and clarity of the display but also contributes to greater energy efficiency. Displays that utilize rare earth elements can achieve the same level of brightness while consuming less power, a crucial consideration in an era where energy conservation and sustainability are increasingly important.

Conclusion

The chemical composition of LCD glass is a complex and finely-tuned blend of materials, each contributing its unique properties to create the high-quality displays we have come to rely on. From the foundational silicon dioxide to the advanced additives like rare earth elements, each component plays a vital role in enhancing the performance, durability, and efficiency of LCD screens. As technology continues to advance, so too will the innovation in LCD glass composition, ensuring that these displays remain at the forefront of visual technology.