Segment LCD Display Module

Segment LCD Manufacturer

Longtech offers standard segment LCDs and wide range of customized solutions to meet your specific needs.

Using our nearly 20 years of expertise and advanced display technologies, we can modify our existing products or develop a completely unique solution for your application. Our dedicated team will be with you at every step, ensuring a successful result.

Standard Specifications

| Item | Out Dimension (mm) | Viewing Area (mm) | Digital size (mm) | Application |

| Standard segment LCD | ||||

| FP1102P | 50.7 x 30.5 | 46.7 x 18.4 | 7.01 x 12.70 | Power meters |

| FP1103P | 50.8 x 30.5 | 44.45 x 16.51 | 6.8 x 12.70 | Instrumentation |

| FP1133P | 137.16 x 46.36 | 131.0 x 31.7 | 13.0 x 26.0 | Instrumentation |

| FP1138P | 50.8 x 30.48 | 44.45 x 16.51 | 4.7 x 10.16 | Instrumentation |

| FP1200P | 92.75 x 46.36 | 86.59 x 31.7 | 13.0 x 26.0 | Instrumentation |

| FP1203P | 69.85 x 38.7 | 65.85 x 26.7 | Instrumentation | |

| FP1209P | 154.0 x 48.7 | 150.0 x 39.7 | Instrumentation | |

| FP1302P | 50.8 x 30.5 | 45.7 x 17.7 | 7.0 x 12.7 | Power meters |

| FP1535P | 69.0 x 29.5 | 65.0 x 27.0 | 6.5 x 15.0 | Power meters |

Request A Quote For More Details

Custom Segment LCD Solution

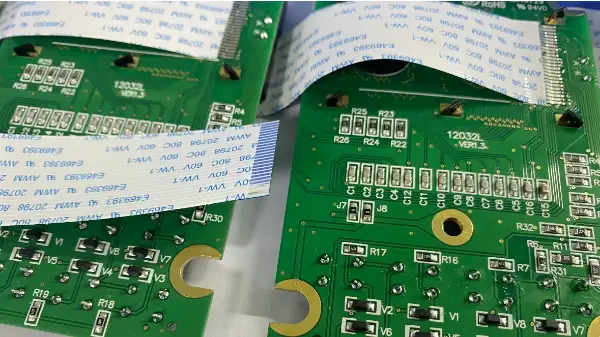

Cable

Modify your cables' length, orientation, and pinout, or add extra connections. Invest in a cable solution that is specifically made to simplify and safeguard your connections.

Interface

To choose the ideal interface for your project, choose from a large range of possibilities or consult with our specialists. To fulfill your design objectives, we can integrate 6800, SPI, I2C, RS232 and more into your display.

Connector

To suit the needs of your application, you may easily adjust any connection on your display. Our engineers can solder any type of header that your display may need, including boxed, right angle, and pin headers.

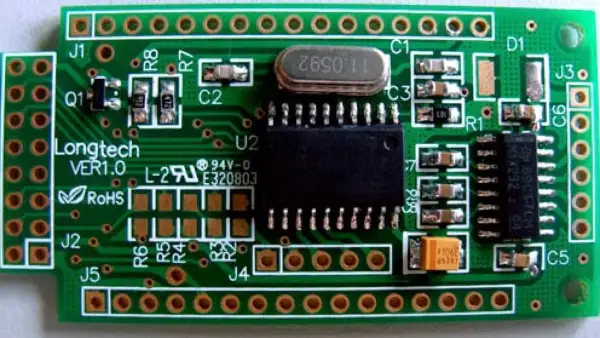

PCB

Choose from a variety of alterations to your PCB's design, size, pinout, and component arrangement to make it a perfect match for your application.

Custom LCD Solution

We have total control over the design, production, and quality control procedures for our display products. Our engineers will collaborate with you to create a prototype to validate and test your idea.

Are you looking for a unique display solution?

All You Need To Know About Segment LCD

This article provides you with everything you need to know about segment LCD. What you’ll learn includes the uses of segment LCD, its parts, the mechanism behind how it works. In the later end, you can check the difference between the small factories and us.

What is Segment LCD?

Segment LCD, or Segment Liquid Crystal Display, is a specific type of display technology that excels in displaying simple images or characters. Unlike full-graphic displays, Segment LCDs are tailor-made for applications requiring distinct, straightforward segments, such as numbers or basic icons. This simplicity doesn’t just cut down on costs; it ensures clarity and efficiency, making Segment LCDs a go-to choice for many industries.

In addition to TN, HTN, STN, FSTN, VA types, polarizer positive and negative mode options are also included in the LCD panel technologies. Different LED backlight options are available in a range of colors, such as white, red, blue, green, amber, RGB, yellow/green, and no backlight option.

These segment LCD displays come in viewing angles of 6:00, 12:00, 3:00, and 9:00 o’clock to satisfy the needs of customer applications. segment LCDs are including different options of polarizer in reflective, transmissive or transflective types.

- Highly Customizable

Segment LCDs offer vast customization options, with the ability to display predefined characters or symbols based on your needs.

- Energy Efficiency

Segment LCDs are known for their extremely low power consumption, making them ideal for battery-operated devices.

- Excellent Visibility

With their high contrast ratios, Segment LCDs provide clear and easy-to-read displays, even in bright lighting conditions.

- Robust Durability

Segment LCDs are designed to withstand a range of operating conditions, offering reliable performance in various environments.

- Cost-Effective

Segment LCDs provide a high-quality, durable display solution at a very economical price point.

- Customizable Backlighting

Segment LCDs can be tailored with various backlight colors to meet specific aesthetic or visibility requirements.

What Are Segment LCD Used For?

Segment LCD are present in almost all industries that need display. These could be the following:

- Automotive

- Industrial

- Medical

- Consumer Electronics

- Marine & Outdoor

- Point-of-Sale

- White Goods

How To Select the Best LCD Display For Your Application

It is not easy to introduce all aspects of selecting the best LCD display, so we have prepared a lot of information on this page for you to delve into. To make sure you can find the information you want quickly, we have prepared this content directory that will jump to the corresponding location when you click on it.

Segment LCD: Passive-Matrix Technology

To comprehend the functioning of Passive-Matrix displays, it is crucial to possess knowledge about their manufacturing process.

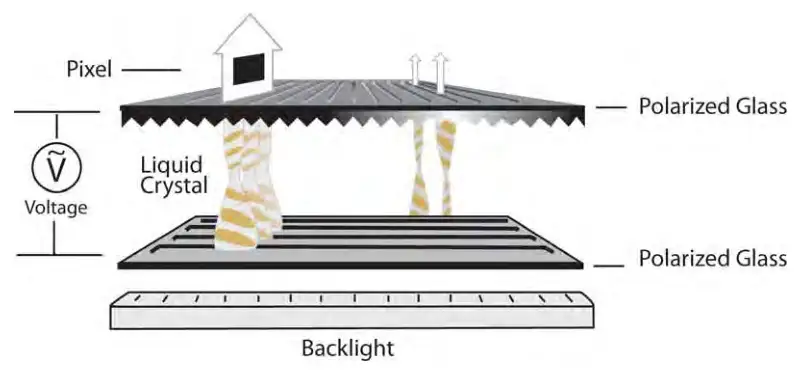

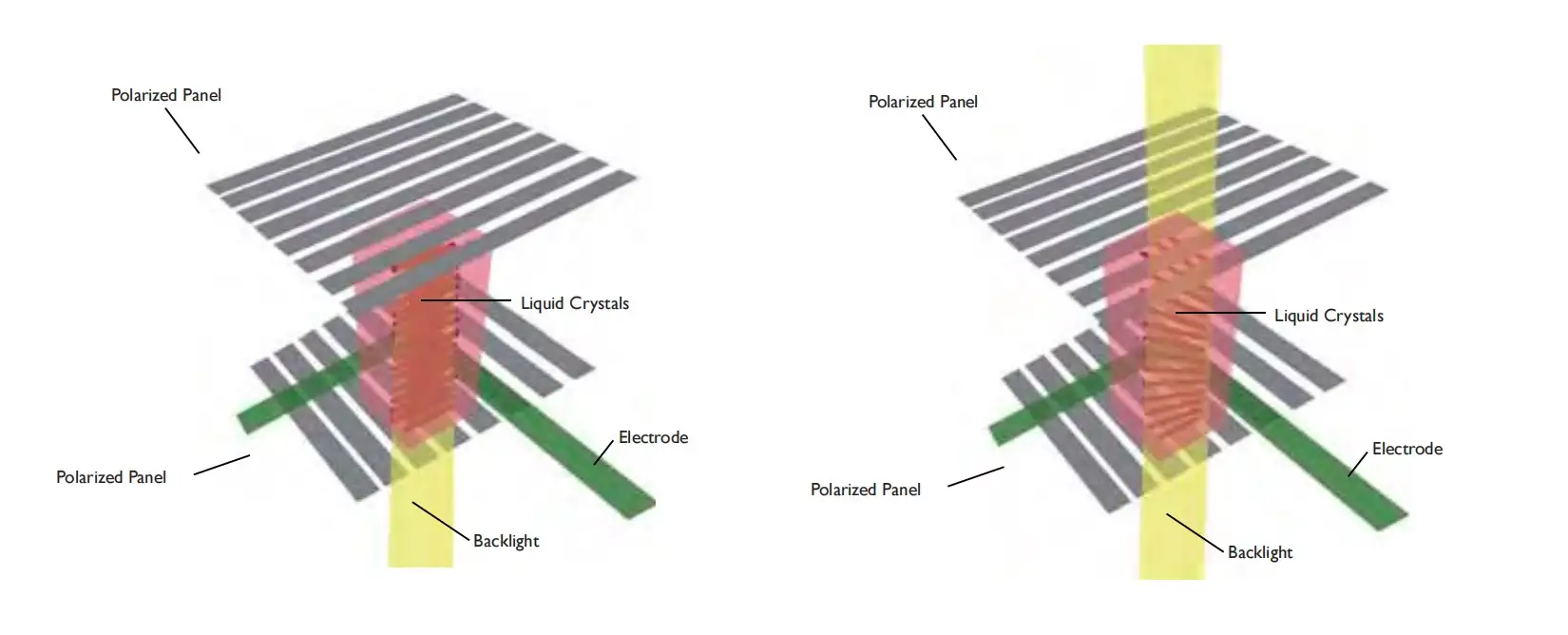

Passive-Matrix displays are made up of two pieces of polarized glass. A unique polymer is put to the non-polarized side of the glass to generate grooves that run in the same direction as the polarizing film.

After that, a liquid crystal substance is applied to one of the polarized glasses’ grooved side. These grooves help the liquid crystal to align with the glass. The second piece of glass is placed on top, grooved side in, perpendicular to the first, forming a row and column pattern.

How Does Segment LCD work?

A pixel is formed when the grooves of two pieces of polarized glass cross. By preventing light from flowing through the top piece of glass, it produces a darker region than the surrounding area. This creates the illusion of pixels being switched on or off. The orientation of the liquid crystal must be altered to prevent light from flowing through. An electric charge is required to do this.

Without an electric charge, the liquid crystal is twisted which changes the angle of the light to match the angle of the top polarized glass. This enables for the passage of light.

When an electric charge is provided, the liquid crystal untwists, but the angle of the light remains constant. As a result, the light is blocked by the top perpendicular piece of polarized glass (as seen in the photographs).

The controllers on the display determine which pixels turn on and off. These controllers are configured to convert user data into predetermined typefaces or to turn on the pixels that have been targeted.

Segment LCD: Display Types

The display types of passive matrix LCD can be categorized into TN (Twisted Nematic), STN (Super Twisted Nematic), and FSTN (Film-compensated Super Twisted Nematic) technologies.

TN Technology

TN (Twisted Nematic) is a popular passive-matrix LCD technology used in everyday applications. The TN technology is made up of a nematic liquid crystal placed between two glass plates. When electricity is introduced to the electrodes, the liquid crystals rotate 90°.

STN Technology

STN (Super Twisted Nematic) technology has quickly established the de facto standard for the majority of passive-matrix LCDs. This technology operates on the same principles as TN screens, however it consumes less power and is often less costly. Unlike TN technology, STN technology's liquid crystals have a 210°-270° twist, allowing for a wider transition zone for gray scaling.

FSTN Technology

FSTN (Film Compensated Super Twisted Nematic) technology is ideal for applications that demand a greater contrast passive-matrix LCD. A film compensation layer is used between the STN display and the back polarizer in FSTN. This extra film improves sharpness and contrast over TN and STN technologies.

Segment LCD: Shape and Icon

Our segment LCDs have unusual shapes, such as round edges, through holes, strengthened glass and so on.

Unusual Shape

One of the most intriguing aspects of segment LCD is their ability to be crafted into unusual shapes, far beyond the standard rectangles or squares commonly seen. This adaptability opens a myriad of possibilities for industrial and consumer applications.

Imagine a Segment LCD shaped to fit seamlessly into the curved dashboard of a car, or tailored to blend into the unique design of a piece of wearable technology. These non-standard shapes are not just about aesthetics; they offer practical benefits too. They allow for more efficient use of space and can be designed to improve user interaction and readability.

- Round

- Octagon

- Through holes

- …

Custom Icon

The process of creating these custom icons involves defining unique segments within the LCD. Unlike standard icons or characters found in typical displays, custom icons are designed to convey specific information that is most relevant to the device’s purpose. This could range from unique symbols representing specific functions in industrial machinery, to easily recognizable icons for consumer electronics.

Moreover, custom icons on segment LCDs ensure that information is conveyed in the most direct and user-friendly manner. This is particularly important in environments where quick decision-making is essential, such as in medical devices or automotive displays. The straightforward nature of these icons, combined with the crisp visibility of segment LCDs, results in a display that is both efficient and effective, enhancing the overall user interface.

Segment LCD: Display Modes

Graphic LCD displays are available in two display modes: positive and negative. The mode that should be selected depends on the application for which the display will be utilized.

Positive Type

Positive type displays provide an image with dark pixels on a light background. Ambient light or a backlight can be used for this type of display and is capable of multiple background colors.

Negative Type

Positive type displays provide an image with dark pixels on a light background. Ambient light or a backlight can be used for this type of display and is capable of multiple background colors.

Segment LCD: Light Modes

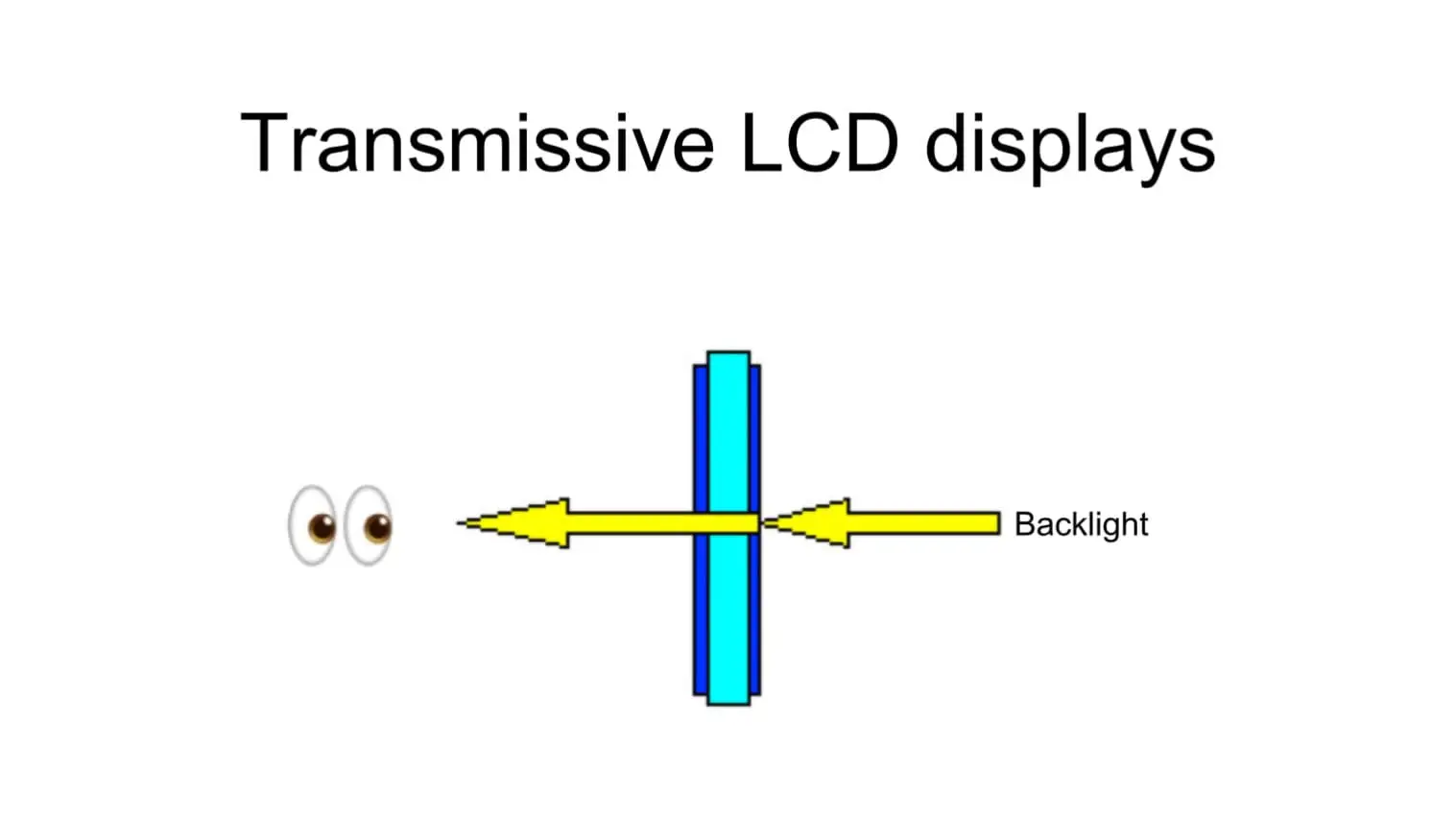

Transmissive

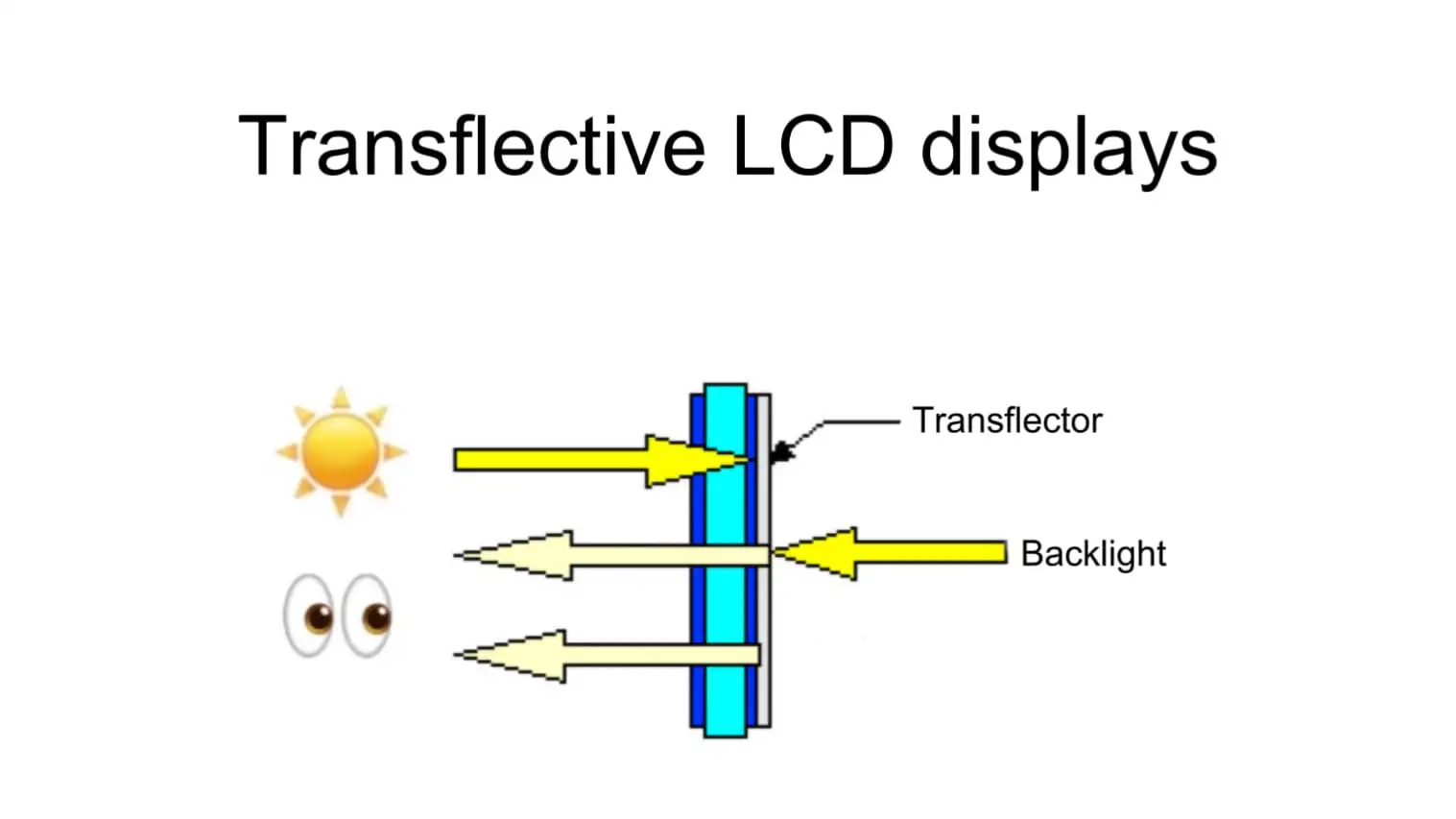

Transflective polarizers have both reflecting and transmitting capabilities and provide the maximum viewing versatility.They may be observed in direct sunshine as well as in low light circumstances when paired with a backlight.

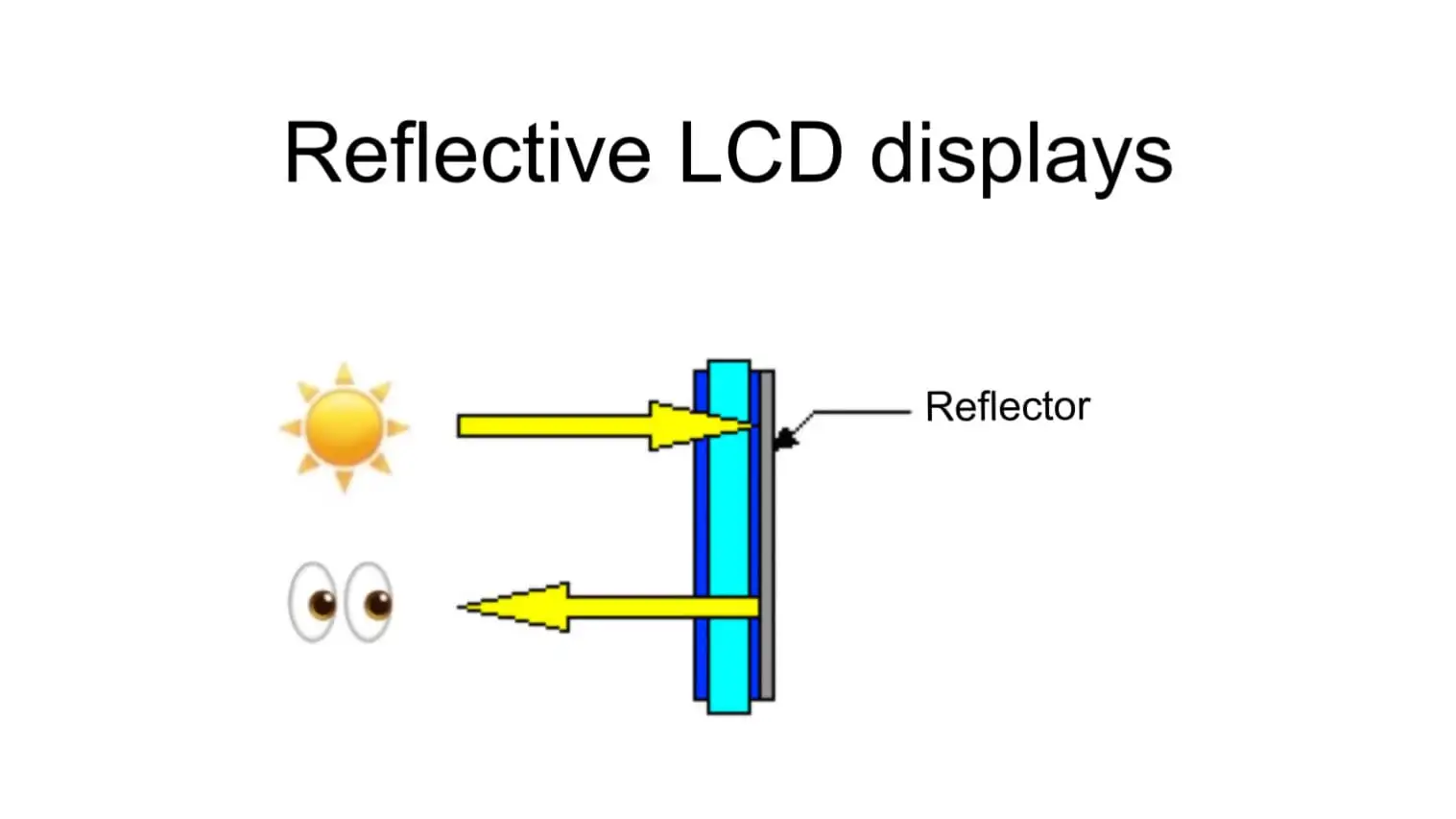

Reflective

Reflective polarizers are employed in high-light conditions or when there is insufficient electricity to run the backlight.

Transflective

Transmissive LCDs always require a backlight and have the maximum display brightness. They are ideally suited for applications that do not need direct sunlight viewing.

Segment LCD: Multi-color about Slik Print

It’s an advanced type of LCD display that utilizes silk printing techniques to create vibrant, multi-colored segments. This technology allows for more dynamic, readable, and aesthetically pleasing screens, enhancing user experience significantly compared to traditional monochrome displays.

How Do Multi-Color Segment LCDs Enhance Display Quality?

Multi-color segment LCDs represent a significant evolution in display technology. They offer a range of colors within each segment, unlike traditional LCDs that are limited to monochrome outputs. But how do these LCDs work, and what makes them superior in terms of display quality?

In these displays, different colored segments are created using silk print technology. This method allows for precise application of colored patterns onto the LCD glass, creating distinct segments that can display multiple colors simultaneously. The result is a screen that is not only more colorful but also offers greater clarity and contrast.

This enhanced display quality is crucial in applications where readability and visual appeal are paramount. From medical devices to industrial control panels, multi-color segment LCDs provide an interface that is both functional and visually engaging.

Advantages of Multi-Color Segment LCDs with Silk Print

Enhanced Visual Appeal: The use of vibrant colors significantly improves the aesthetic of the display. This is crucial in sectors where user interface plays a key role in product appeal.

Improved Readability and Contrast: With multiple colors, these LCDs offer superior readability and contrast. This is especially beneficial in environments with varying lighting conditions, ensuring that information remains clear and accessible.

Customization and Flexibility: Silk print technology allows for a high degree of customization in color patterns and designs. This flexibility is essential for tailoring displays to specific industrial or commercial needs.

Increased User Engagement: The dynamic and colorful displays engage users more effectively, making interaction with devices more intuitive and enjoyable.

Durability and Reliability: These displays are not just about looks; the silk print method contributes to the overall durability and longevity of the screen, ensuring reliable performance over time.

Wide Application Range: From medical devices to automotive dashboards, these LCDs can be adapted to a wide range of applications, thanks to their versatile design capabilities.

Enhanced Information Processing: The clear distinction between colors aids in quicker and more accurate information processing, which is vital in high-stakes environments like healthcare and transportation.

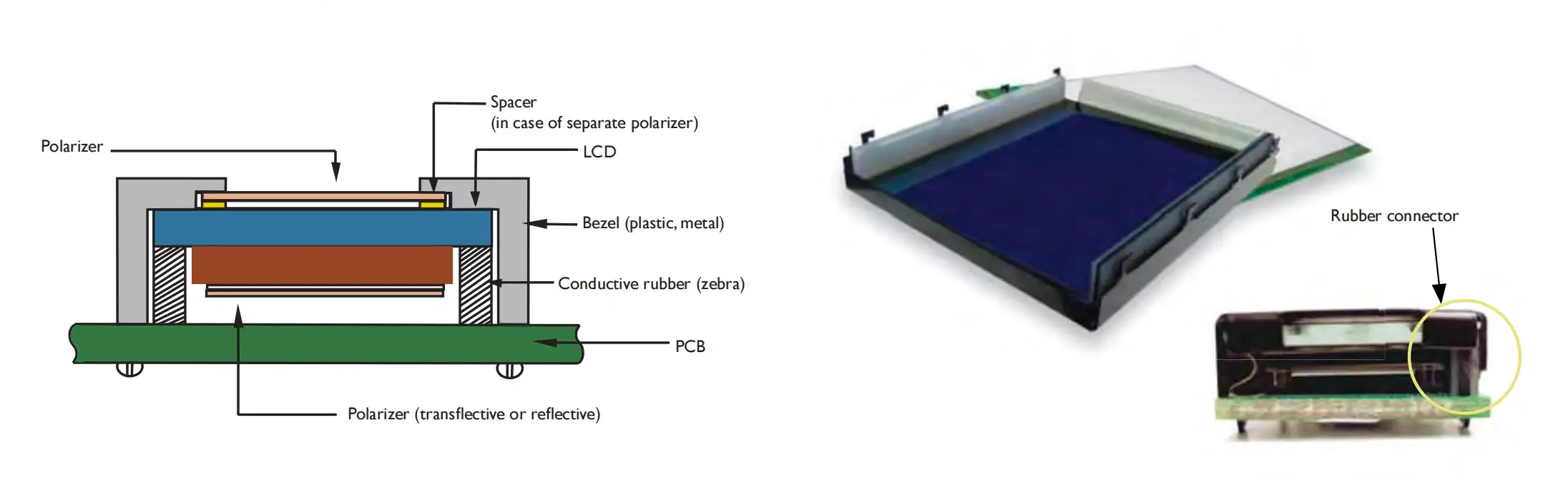

Segment LCD: Connection Methods

The suggested techniques for connecting the LCD screen to the driving circuit are shown in the schematics below.

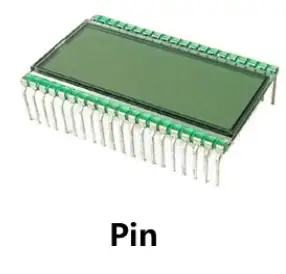

Pin Connector

A metal connector called a pin connector is glued to the LCD glass and fits onto it. Every pin connection has holes that connect to the PCB and covers an ITO trace on the glass. The PCB’s plated thru-holes connect to the controller/driver’s SEG and COM lines. Solder is used to join the PCB to the pin connection. This kind of connection has a strong track record of stability and is appropriate for modest production runs.

Rubber Connector

The rubber connection is a material strip that is sandwiched between the glass and the PCB. The PCB holds it in place while mechanical force is used to construct it. This kind of connection is composed of an insulating layer covering a conducting substance. The conductive material lines up and links the ITO traces on the glass with the COM & SEG traces on the PCB when it is positioned between the glass and the PCB. With its extended performance lifespan, the rubber connection is perfect for any application.

How do you drive a segment LCD?

Driving a Segment LCD involves a nuanced understanding of its structure and the careful orchestration of its electronic components. At its core, it’s about managing electrical signals to control each segment, creating the desired visual output.

What Are the Core Principles of Driving a Segment LCD?

Driving a Segment LCD involves a series of steps, starting with the generation of the required electrical signal. This signal is then sent to the appropriate segments through a combination of drivers and controllers. The drivers are responsible for providing the right amount of voltage to the segments, while the controllers manage the overall operation of the display, dictating which segments are active at any given time.

How Can Common Issues in Driving Segment LCDs Be Troubleshot and Resolved?

Even with the best design and implementation, issues can arise in driving Segment LCDs. Common challenges include segment ghosting, uneven brightness, and electrical interference. Addressing these issues often involves recalibrating the driving voltage, adjusting the layout, or even replacing faulty components. Regular maintenance and monitoring are also vital for ensuring the long-term performance of these displays.

What Steps Are Involved in Implementing and Driving a Segment LCD in a System?

Implementing a Segment LCD into a system involves several key steps:

- Designing the Segment Layout: This is tailored to the specific application, whether it’s for a simple calculator or a complex industrial instrument.

- Selecting the Right Components: Choosing the appropriate driver ICs and controllers that can efficiently manage the electrical signals.

- Integration with the System: Physically installing the LCD into the device and electronically connecting it to the system’s circuitry.

- Programming and Calibration: Ensuring that the LCD responds correctly to the system’s commands, often involving software programming and calibration processes.

Request A Quote For More Details

Why Choose LCD Display From Longtech?

Diverse Product Line

With a broad array of LCD and OLED solutions, we cater to every tech requirement.

Unwavering Quality

Our products meet international standards, embodying top-tier quality and consistency.

Competitive Pricing

High quality meets affordability in our competitively priced products.

Low MOQ

Our production is flexible and will meet your requirement of ordering varying quantities.

Exceptional Service

Our customer service team ensures a seamless, professional experience.

Trusted Partner

Clients trust us for our reliability and unwavering commitment to their success.

More Than Just an LCD Display Manufacturer

Superior in-house production ensures quality and efficiency, unlike small factories with higher defect rates.

Small Factories

Our Advantages

Small Factories

Our Advantages

Small Factories

Our Advantages

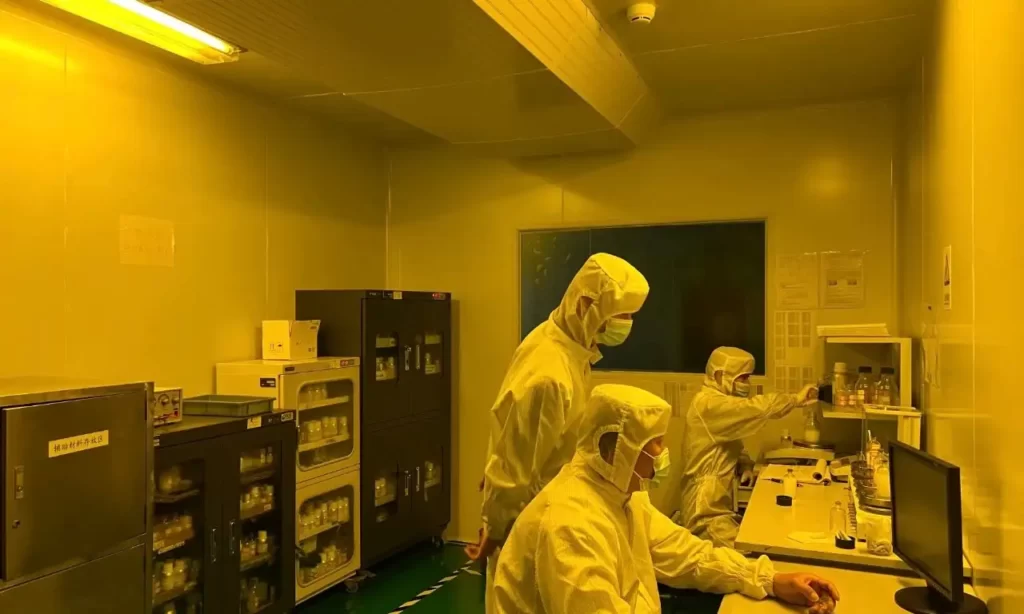

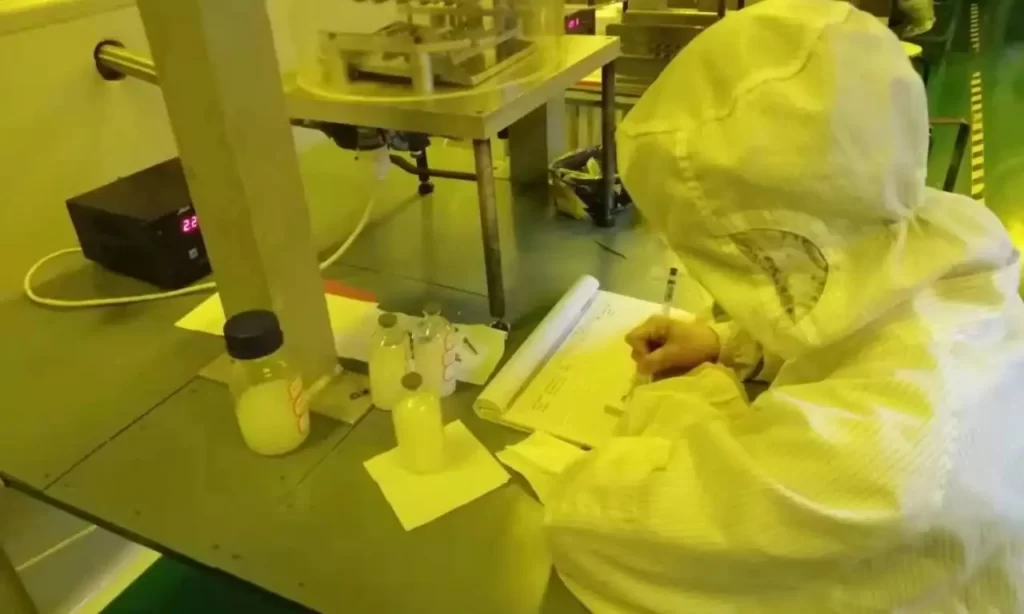

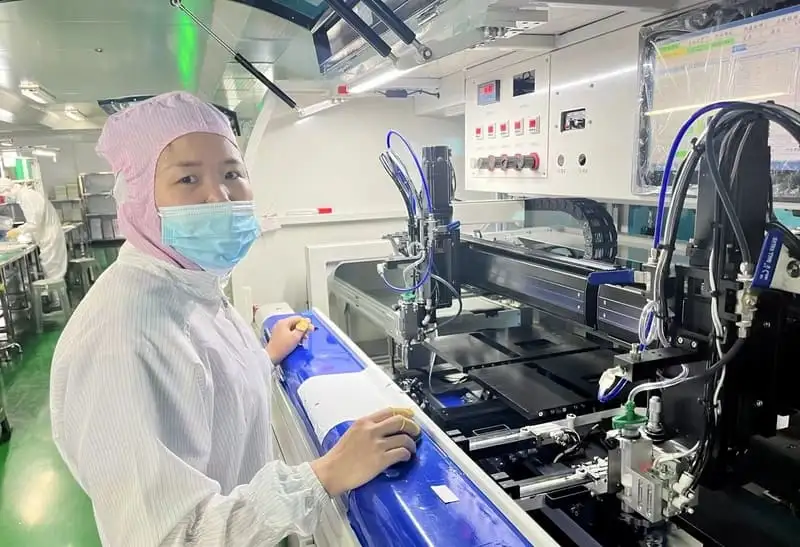

A Few Steps of Our Production Process

There are more than 30 steps for the production process of display and here only a few typical production steps are displayed.

Frequently Asked Questions

We have compiled the most frequently asked questions about our LCD display here for your convenience, but please feel free to contact us if you have any additional questions.

We offer detailed datasheets and technical guides for all our products. These resources provide comprehensive information to facilitate the integration of our LCDs into your design. Our expert team is also available to assist you with any specific queries or challenges you may face.

Longtech specializes in custom solutions. Our team can work closely with you to understand your unique requirements and develop a customized LCD product that perfectly fits your application.

Our LCDs come with various options for temperature range, contrast adjustment, and backlighting to ensure optimal display performance under different conditions. Our technical team can also provide guidance on how to select and configure these options based on your specific needs.

Yes, we provide libraries and sample code for most of our LCD products. These resources can help you get started quickly with programming the display for your application.

How do I diagnose and resolve issues with the LCDs?

At Longtech, quality is our top priority. We follow a strict quality control process which includes various stages of testing and inspection to ensure our products meet the highest standards.

Yes, we understand the need for testing before making a large purchase. Please contact our sales team to discuss the minimum order quantity for your chosen product.

Lead times can vary depending on the complexity of the customization and the quantity required. Our team will provide a more precise timeline once the specifications are finalized.

We have extensive experience in global shipping and can coordinate logistics to any part of the world. Our team can work with you to determine the best shipping method based on your location, budget, and timeline.

Absolutely, our commitment to our customers doesn't end after a sale. We provide ongoing technical support to ensure the successful integration and operation of our products in your application.

We stand by the quality of our products. In the unlikely event that you receive a defective product, please contact us immediately, and we will work to address and rectify the issue promptly.

Request an Instant Quote for Your Projects!

If you’ve got LCD display concerns and specific requirements, it’s time to speak to one of our Industry Experts. We’re glad to answer any questions you may have!

Message us, we will be in touch shortly

LONGTECH DISPLAY

- Address: 5F No.8-5 Xiayang Road, Haicang Area, Xiamen China

- Email: zhong@longtech-display.com

- Tel: +0086-592-6060928

- Fax: +0086-592-6682033

*We respect your confidentiality and all information is protected.